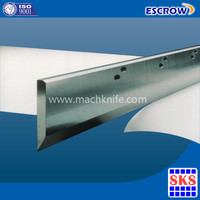

drum chipper blade with high wear-resistance

Product Quick Detail

- Place Of Origin

- Chian(Mainland)

- Material:

- wearable metals as 5CrW2Si,6CrW2Si,9Cr Si,H13,Cr12MoV,SLD

- Hardness:

- HRC40~68 degree

- Parallelism Tolerances:

- within 0.003mm

- Certification:

- ISO9001:2008

- Property Of Company:

- manufacturer/factory/supplier

- Packaging

- anti-rust oil ,plastic bag , plywood case (or as customers' request)

- Delivery

- depends on your quantity(usually within 3--4 weeks )

Specifications

Material:

Wood chipper knife for woodworking industry made of tool steel, high speed steel, hard alloy steel and tungsten carbide, etc. can all be provided here.

| D2 Tool Steel (EN/DIN 1.2379) | Quality tool steel for soft timber |

| M2 6.4% SW HSS(EN/DIN 1.3343) | A premium grade HSS for general use |

| T1 18%W HSS(EN/DIN 1.3355) | Suitable for hardwoods because of its tolerance to high heat |

| A8 | A8 steel has a good tenacity ,high abrasive resistance and it can resist to high temperature fatigue |

Features of drum chipper blade/cutter :

1,Suitable for hard and soft wood.

2,Easures clean equal sized chips and longest possible time.

3,Angle of cutting edge: 26° to 40° as per type of machine and sort and condition of wood.

4,Strong and sharp cutting edge Can be used for varied angle cutting

5,Selection of the highest quality raw material with state-of-the-art heat treatment process.

6,Through hardened and triple tempered steel will maximize knife life while providing consistent, clean cuts.

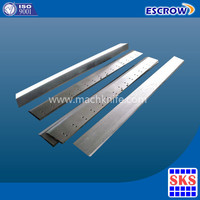

Specification : (According to customer's samples or sample map made to

order .) DRUM CHIPPER BLADES

| Model | Specification(mm) | Length | Width | Thickness |

| BX216 | 600×180×20 | 600 | 180 | 20 |

| BX218 | 780×220×20 | 780 | 220 | 20 |

| BX218A | 875×220×20 | 875 | 220 | 20 |

| BX218D | 850×220×20 | 850 | 220 | 20 |

| BX2113A | 780×220×20 | 780 | 220 | 20 |

| BX2113C | 665×220×20 | 665 | 220 | 20 |

| BX1710 | 258×75×6.5 | 258 | 75 | 6.5 |

| BX1216 | 482×110×14 | 482 | 110 | 14 |

| BX1112 | 342×110×14 | 342 | 110 | 14 |

| BX2110 | 540×220×20 | 540 | 220 | 20 |

Why do you choose us ?

1,We are a China-based factory ,manufacturer.

2,Passed the ISO9001 Quality Certification in 2008.

3,Forging each individual blade to ensure a long working life.

4,Triple-tempering to retain the hardness while toughness kept.

5,SKS offers HSS tipped knife/Tungsten Carbid tipped blades.

6,Laser marking is available.

7,Short delivery time,considerate packaging.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 1992

- Address: No.9 Mingjue Industrial Park,Lishui Nanjing,China

- Contact: May Zhu