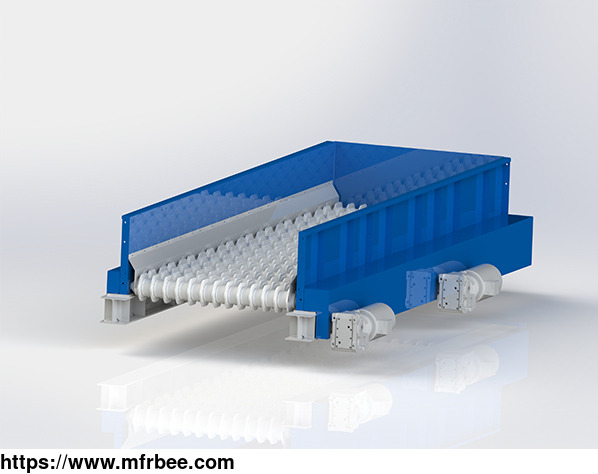

DISC SCREEN SEPARATOR

Specifications

The disc screen separator from Hengchuang is used to separate small volumes of waste and inert garbage. The trash on the dish-shaped sieve of the dish-picker vibrates as the sieve rotates. To

achieve the goal of sorting by trash sorting machine, there is a space between the dish sieve according to the size and weight of the trash. Organic waste disc screens are extensively used in trash

disposal as screening equipment.

Disc Screen Separator Technical Advantages

Not easy to block by Hengchuang organic waste disc screening

Convenient disc replacement

Effective separation of organic waste and mixed waste

Small floor space and energy consumption

Low maintenance cost

Modular design for easy maintenance

Disk Screen Separator Application

Difficult to clog

The disc tray is simple to replace in Hengchuang organic waste disc screening.

Separation of organic trash and mixed waste that works

Low energy use and a small footprint

Inexpensive upkeep

Modular architecture for ease of upkeep

Construction and Demolition Discs Screen Application

Construction and demolition discs are used in a variety of applications involving the cutting or grinding of materials such as concrete, brick, block, and asphalt. From Hengchuang solid waste

management equipment manufacturer, These discs are typically mounted on a circular saw or angle grinder and are used in the construction and demolition industry to cut or grind through tough

materials.

Municipal Solid Waste Disc Screening

The main function of municipal solid waste disc screening is to separate and size waste materials based on their physical characteristics, such as size, shape, and density. This MSW segregation

machine process is important for several reasons:

To separate recyclable materials by disc screen separator: municipal solid waste disc screen can be used to separate recyclable materials, such as paper, plastic, and metal, from non-recyclable

waste. This helps to reduce the amount of waste that goes to landfills and promotes the recycling of valuable resources.

To improve the efficiency of waste processing by organic waste disc screens: municipal solid waste disc screening can help to improve the efficiency of waste processing by removing large,

non-organic materials from the waste stream. This can help to reduce the amount of waste that needs to be processed and can also help to improve the efficiency of downstream processes such as

composting or incineration.

To produce a consistent end product by organic waste disc screens: municipal solid waste disc screening can help to produce a more consistent end product, such as compost or fuel, by removing

contaminants and ensuring that the final product meets specific size and quality requirements.

Disc Screen Separator Operating Principle

Through the gap between disk screens, Hengchuang disc sieve filters items smaller than the gap.

The disc screen separator is rotated by a reducer driving system, and the shaft drives the screen disk to rotate. Materials smaller than the disc gap are separated, while those larger than the disc

gap are sent to the next step.

Screen disc are put on each shaft of the disc sieve. Depending on the material, the screen discs might be hexagonal, star-shaped, triangular, or other shapes. The size of the screen disks and the

distance between them can be adjusted to meet specific needs.

If you need any kinds of waste management equipment, please contact us, as a professional solid waste management equipment manufacturer, Hengchuang is willing to offer you high quality products.

- Country: China (Mainland)

- Founded Year: 253000

- Address: Room 801, office building, No. 1697, Dongfanghong West Road, Xinhu sub district office, Decheng District, DeZhou City, Shandong Province

- Contact: hcmswrecycling com