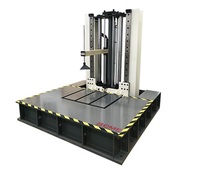

Drop Test Machine

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Shaanxi Province, 712023 China

- Packaging

- Wooden Packaging

- Delivery

- 3 months

Specifications

WHAT IS DROP TESTING?

Drop testing simulates of the free-fall impact drop that products or packaging products may experience during shipping and handling. Drop testing is mainly to evaluate the ability of product or

packaging to withstand drops during transportation and loading and unloading, so as to improve product and packaging design.

CME is one of the leading drop test equipment suppliers in China. Contact us for the drop test machine price now!

Drop impact testing machine CME offers

CME is a professional drop tester manufacturer since 2006.

KRD40 Zero Distance Drop Test Machine

KRD41 Small Drop Test Machine

KRD42 Double Lift Zero Distance drop impact test Machine

HOW TO CHOOSE DROP TEST MACHINE?

01

KRD40 series zero-distance drop tester

KRD40 series zero-distance drop tester mainly simulates the resistance to drop and impact of large and heavy packaging products. It can realize the drop test of the edge, surface, and angle of the

sample. This equipment is mainly used to evaluate the ability of product or packaging to withstand drops during transportation and loading and unloading, so as to improve product and packaging

design.

02

KRD41 series small drop tester

KRD41 series small drop tester is suitable for free-fall tests of small consumer electronics and components.

03

KRD42 series double-lift drop tester

KRD42 series double-lift drop tester is mainly suitable for large size packaging products to resist drop impact performance, its powerful power system and unique sample support for easy loading and

unloading of oversized, overweight items, and automatically rise to the set height, complete the drop test.

WHY DO DROP SHOCK TEST?

There are two objects for drop test method, one is the product without packaging, the other is the packaging product. The reason for performing a drop test for product or component is to evaluate

the product design and materials robustness when it is exposed to a free-fall impact force. The purpose of performing a drop shock test for packaging products is to evaluate whether the packaging

design is suitable, overpackaging or less-packaging, so as to improve the packaging design to save the cost & protect products.

For more information about reliability test equipment, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2006

- Address: No.3 Upgrade Demonstration Base, West of Yongchang Rd., High-tech Zone, Xianyang City, Shaanxi Province, 712023 China

- Contact: Echo Yang