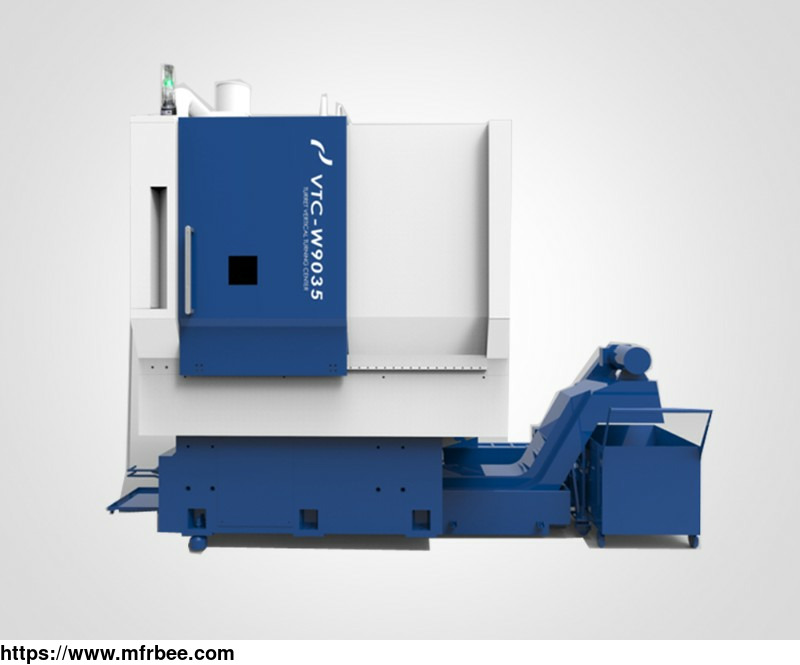

UNIVERSAL HORIZONTAL LATHE

Specifications

The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas design, compact structure, and strong operability.

The cnc turning lathe machine sheet metal adopts a fully enclosed protective structure with good chip removal, drainage, and leakage effect.

UNIVERSAL HORIZONTAL LATHE FEATURES

The mineral-cast rectangular hard rail bed has good shock resistance, low thermal sensitivity coefficient, and good overall rigidity.

The mineral casting spindle box has low vibration, high speed, and high efficiency, which is about 30% higher than the market average efficiency.

According to industry requirements, imported spindle units are specially ordered.

The chip conveyor is separated from the water tank, making cleaning and maintenance more convenient.

The main processing objects are the rough and fine turning of the common 12-22 inch passenger wheel hubs and the car's wheel hubs, it can also be used for the turning of similar disc parts.

UNIVERSAL HORIZONTAL LATHE WORKING PRINCIPLE

The working principle of the horizontal lathe: The main function of the braking device of the CNC horizontal lathe is to be used in the parking process of the lathe, to overcome the rotational

inertia of the moving parts in the headstock, to control the spindle to quickly stop rotating to shorten the auxiliary time and thus to horizontal The purpose of the lathe to install the brake.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Middle East,Americas

- Founded Year: 2008

- Address: North of Yong'an Road, Industrial Development Zone, Yanzhou District, Jining City,Shandong Province

- Contact: deed machinetool