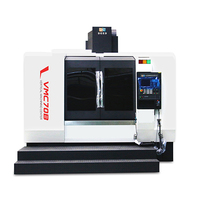

CNC DIE MAKING MACHINES

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Europe,Middle East,Americas

- Founded Year:2008

- Address:North of Yong'an Road, Industrial Development Zone, Yanzhou District, Jining City,Shandong Province

- Contact:deed machinetool

Other products from Shandong Deed Precision Machine Tool Co.,Ltd.

Relate products of CNC DIE MAKING MACHINES

Features of Potato Starch Making Machine Potato Starch Making Machine Potato Starch Process Description and Flowchart: Goodway has been continuously developing potato starch machine since 1991 to maximize product quality. From potato root hopper until the packaging stage, we ...

CNC machining is short for Computer Numerical Control machining which is an important processing method for modern industries. As an excellent China cnc machining parts manufacturer, HQ provides various custom CNC machining products and CNC machining prototype services for ...

Wholesale Aluminium Milling Service Since its excellent strength-to-weight ratio, aluminium is one of the most commonly used metals. HQ routinely provides aluminium machining parts. Custom Aluminum Machining General Information Processes Lead Time Applications CNC Milling CNC ...