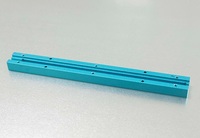

Precision Injection Molding

Specifications

At Packson, we specialize in manufacturing custom precision mold components and machined parts that meet or exceed international quality standards, including ISO 9001 and 13485. Our team is

dedicated to building custom, durable, high-quality precision mold parts with the spirit of craftsmanship.

We take pride in our precision machining process, which is led by engineers with over ten years of experience. This process enables us to provide our customers with more efficient, high-precision,

and economical designs and products. We are committed to delivering precision molds that consistently meet or exceed industry-standard tolerances, up to ±0.005mm.To ensure the quality of our

products, we use precise equipment for production and manufacture. We follow ISO 9001 and ISO 13485 quality control processes to ensure that every product meets our high standards. Our world-class

production and testing equipment, including KEYENCE, Makino, CHARMILLES, Zeiss, and NISSEI, provides a strong guarantee for the precision of your products.

Precision mold parts must meet certain performance requirements to ensure their durability and longevity.

1. Strength and Toughness: Precision molds and tooling components often operate under harsh conditions, which can result in brittle fractures due to large impact loads. Therefore, it is essential

for precision molds to have high strength and toughness to prevent sudden breakage during the working process. The toughness of molds and tools depends on factors such as carbon content, grain

size, and microstructure of the material.

2. Fatigue Fracture Performance: High-precision injection mold parts often experience fatigue fracture during operation due to the long-term effects of cyclic stress. This can include multiple

small energy impacts, tensile, contact, and bending fatigue fractures. This characteristic of custom molding and tooling depends on factors such as strength, toughness, hardness, and content of

inclusions in the material.

3. High-Temperature Performance: When the working temperature of precision molds and dies is high, the hardness and strength of the material can be reduced. This can lead to early mold wear or

failure due to plastic deformation. Therefore, it is important for the mold material to have high tempering stability to ensure that the mold maintains high hardness and strength at working

temperature.

4. Cold and Hot Fatigue Resistance: Some molds are subjected to repeated heating and cooling during the working process, which can cause the cavity surface to be pulled and stressed. This can lead

to surface cracking and spalling, increased friction force, and reduced dimensional accuracy. Hot and cold fatigue is one of the main forms of hot working tool failure.

5. Corrosion Resistance: In some cases, molds may be exposed to strong corrosive gases during operation, such as in plastic injection molding. These gases can erode the cavity surface, increase

surface roughness, and intensify wear loss effects. This is due to plastic decomposition that produces elements such as chlorine and fluorine that precipitate HCI and HF.

The Components of Precision Moulds

The success of precision mould includes the following:

Precise control of the mold cavity size

Precision of parting surface

Exact solution of material

Strict requirement for a tolerance

Venting design

Material flowing

Cooling system

Choosing of steel material

Overall excellent tooling design

Process of Precision Mould

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer

Send us your part 3D to get your mold and part quote

Confirm quotation and order issues, Packson starts the mold and precision mold parts order process

Making DFM and create processing solution

Tooling design review by Packson engineers

Get approval of the design, Packson start building your injection mold

Customer checks samples for approval

Part mass production begins

Applications of precision moulding and moulds

As mentioned earlier, precision mould is used for the development of various products. But this technology has really revolutionized the development of lenses in various applications because it

allows OEM to manufacture cheaper and stronger glass-free lenses. Glass lenses are very delicate, difficult to manufacture, and expensive, but plastic optical lenses have completely changed the

optical industry. Precision molding is used for the development and mass production of precision spherical, diffraction, free-form surface, aspheric, and other types of lenses. It is a high-quality

product with a perfect optical surface finish.

As a professional precision mould part manufacturer, we provides custom molding services, medical injection moulding, precision mould parts, precision moulds and components, precision mold parts,

precision mold components, injection molding china, etc. For more information, please feel free to contact us!

- Country: China (Mainland)

- Address: No.2 Building,Rongtong Industrial Park,Wulian Village,Fenggang Town,Dongguan,China

- Contact: Packson .com