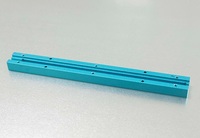

Silicone Rubber Mold

Specifications

Silicone rubber is a kind of elastic material, which is widely used in industry and family. It has become an important part of our life. Meanwhile, silicone moldings are becoming more and more

important in the world because it is widely used in a variety of industries like medical, children's consumer parts and automotive parts so on.Packson has more than 15 years of experience in

silicone rubber mold and silicone rubber mould making. As one of the most famous silicone mold factory, we ensure that you will get the highest quality silicone rubber mold products at some of the

most competitive prices in the industry.

Process of Silicone Rubber Mold

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer

Send us your part 3D to get your silicone rubber mold and part quote.

Confirm quotation and order issues, Packson starts the silicone rubber mold and part order process.

Making DFM and create a silicone rubber mould making solution.

Tooling design review by Packson engineers.

Get approval of the design, Packson start building your silicone rubber mold.

Customer checks samples for approval.

Part mass production begins.

Advantage of Silicone Rubber Mold

At extreme temperatures, silicone rubber provides a wide range of resistance in hot and cold environments. In addition, compared with traditional rubber, silicone rubber provide better tensile

strength. Please check the following advantages of silicone rubber mold:

High-temperature resistance and low-temperature performance.

Good thermal stability.

Excellent electrical insulation, even if immersed in water, will not reduce the insulation performance.

Low chemical reactivity.

Silicone rubber can be applied in different molding way: silicone rubber mould making, die-cutting, extrusion.

Application of Silicone Rubber Mould Making

The application of silicone rubber mould making is involved in all kinds of industries by liquid silicone rubber molding and solid silicone rubber mould making, including automotive, healthcare,

general industry, infant care, consumer goods, and electronic products. All of these areas require silicone rubber mold that is easy to form and create parts efficiently and economically.

Automotive

Noise elimination and shockproof for automotive driveshafts

Sealing rings

O-rings

Window and door seals

Electrical

Protective jacket for wire and cable

Electrical safety stinger covers

Silicone seals for electrical parts

Electric button

Medical

Disposable catheter

Personal healthcare part

Breathing Mask

As a professional mould part manufacturer, Packson has high-quality medical silicone injection molding for sale. Welcome to contact us if needed.

- Country: China (Mainland)

- Address: No.2 Building,Rongtong Industrial Park,Wulian Village,Fenggang Town,Dongguan,China

- Contact: Packson .com