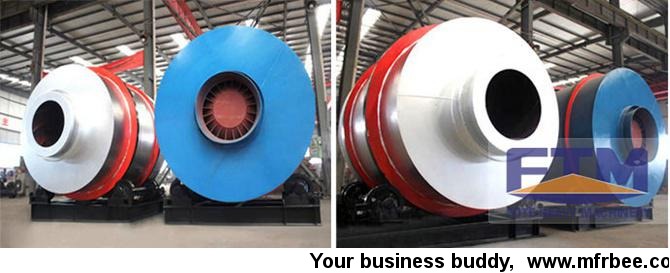

Sand Dryer

Product Quick Detail

- China

- Henan

- Packaging

- standard containers, bare main machine, motors and small parts are packed in wooden cases.

- Delivery

- 20 Days

Specifications

Outer Cylinder Length: 6 - 8.5 m

Production Capacity: 20 - 99 t/h

Application Range: Slag industry and sand making industry.

Processible Materials: River sand, artificial sand, silica sand, yellow sand, mineral sand, mineral powder, grain slag, blast furnace slag, coal ash, coal cinder.

Sand Dryer Introduction:

Sand dryer is a machine that is able to process large quantities of materials and the advantages include reliable operation, elastic running principle, strong adaptability and big processing capacity. Sand dryer is generally suitable for drying granular materials and has good drying effect especially when drying sand, river sand and quartz sand in building material, chemistry and casting industry.

This machine is mainly composed of rotary part, lifting board, transmission part, supporting part and seal ring. The dryer machine produced by our company uses new lifting board with many functions of guiding, current sharing and material lifting, and the materials can be comprehensively distributed on the radial sections of the dryer machine and the material curtain is in the thin, average and full state and the materials can fully contact the hot air, thus achieving the aim of making full use of the heat.

The dryer machine produced by our company uses reasonable running parameters, and the coal and electricity consumption is reduced by over 10-15% and the output per machine is improved by over 10-15%, so that it has been widely used in the cement plants and ore beneficiation plants.

Sand Dryer Features:

Sand dryer machine has advantages of large capacity, wide application range, small flow resistance, larger operation fluctuation range, ease operation and so on, so it’s often used for drying river sand, artificial sand, quartz sand, slag, cinders, etc.

Sand Dryer Working Principle:

Sand will be fed into the hopper through belt conveyor and bucket elevator, and then be fed into the end hopper through feeding machine or pipes. The inclination of feeding pipe should be larger than natural inclination of materials, for sand smoothly entering into the dryer. Dryer drum is a slightly inclined rotating cylinder with horizontal lines. Materials are fed from the higher end, while heat medium enters from low-end, forming counter-current contact with materials. Heat medium flowing into the cylinder together with material is available. As the rotation of the cylinder, materials run to the end of the sand dryer under gravity. Wet material, in the course of the cylinder moving forward, directly or indirectly get heat from medium heat, for drying wet material, and then discharged through the spiral conveyor or belt conveyor installed at the end of discharging port. Sand dryer is equipped with lifting board on the cylinder wall, and the lifting board plays the role of lifting and falling down materials, increasing the contact surface between material and air flow, so as to improve the drying rate. Heat medium is generally divided into hot air, flue gas and others. Generally, heat medium after being dried needs to be cleaned the materials filled in gas by cyclone dust collector. If you need to further reduce exhaust dust content, pass through bag filter or wet dust collector before discharging it.www.china-ftm.com/pros/sand_dryer.html

Technical Datas of Sand Dryer

| Item | φ2.0×6m | φ2.5×6.5m | φ2.7×7m | φ3×7m | φ3.2×7m | φ3.6×8m | φ4.2×8.5m | |

| Diameter of outer cylinder (m) | 2.0 | 2.5 | 2.7 | 3 | 3.2 | 3.6 | 4.2 | |

| Length of outer cylinder (m) | 6 | 6.5 | 7 | 7 | 7 | 8 | 8.5 | |

| Cylinder volume (m³) | 18.84 | 31.89 | 40.5 | 49.46 | 56.26 | 81.38 | 118 | |

| Rotating speed of cylinder (rpm) | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | |

| retention time of materials (min) | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | |

| Initial moisture of materials (%) | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | |

| Final moisture of materials (%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Highest intake air temperature ( ℃ ) | 750-900 ℃ | 750-900 ℃ | 750-900 ℃ | 750-900 ℃ | 750-900 ℃ | 750-900 ℃ | 750-900 ℃ | |

| Production capacity (T/H) | Slag | 20-25 | 25-30 | 30-35 | 35-10 | 40-45 | 50-65 | 70-85 |

| Coal ash | 10-17 | 17-21 | 20-25 | 23-27 | 25-30 | 30-45 | 45-63 | |

| Yellow sand | 20-27 | 25-40 | 27-45 | 30-45 | 35-50 | 55-75 | 75-99 | |

| Motor type | Yr160m-4 | Yr132m-4E | Yr160m-4 | Yr160m-4 | Yr132m-5E | Yr160m-4E | Yr160m-4E | |

| Motor power (kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 11×4 | 15×4 | 18.5×4 | |

| Reducer type | XWD-6 | XWD-6 | XWD-6 | XWD-6 | XWD-6 | XWD-8 | XWD-8 | |

| Velocity ratio of reducer (I) | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Asia,Emerging Markets,Middle East,Oceania

- Founded Year: 2014

- Address: 河南省郑州国家高新技术产业开发区檀香路8号

- Contact: fotemachinery china

.jpg)

Bentonite Dryer

Bentonite Dryer

Industrial Drying Machine

Industrial Drying Machine