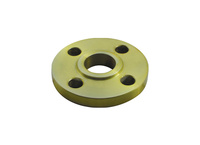

QSL3T-3 3PCS Ball Valve Socket-Welding

Specifications

The three-piece low-temperature ball valve socket weld belongs to the three-piece low-temperature ball valves series. The valve body is composed of three sections. The two ends are socket welding

connection surfaces. After special low-temperature treatment, the temperature resistance is -50 degrees and the pressure resistance can reach 7.0. MPA.

Engineering pressure: 7.0MPA 1000WOG

Operating temperature: -50 degrees to 230 degrees

QSL3T-3 3PC Ball Valve Socket-Welding Dimensions

SIZE L W H

1/2" 73 105 54

3/4" 82 105 63

1" 90 125 63

1-1/4" 112 140 84.5

1-1/2" 120 162 93

2" 146 162 101.5

2-1/2" 177 215 120

3" 205 224 125

4" 265 251 180

3PC Ball Valve Socket-Welding VS Butt-welding

1. Material:

Both material of 3 pc ball valve socket-welding and butt-welding ball valve can be CF8,CF8M,CF3M.

2. Pressure:

Both pressure of 3 pc ball valve socket-welding and butt-welding can be 200WOG, 800WOG, 1000WOG, 1500WOG, 2000WOG

3. Range of Applications (Difference):

Stardard: ANSI, BS, DIN (similarity)

Sealing Material: PTFE, R-PTFE (similarity)

Connection type:Socket-Welding end

4. Installation (Difference):

3PC ball valve socket-welding is to extend the pipe into the valve body for welding, the strength of welding seam, stress state is better than socket welding type.

QSL3T-3 3PC Ball Valve Socket-Welding FAQs

What Are The Advantages Of Ball Valves?

Ball valves are generally the least expensive of any valve configuration and have low maintenance costs. In addition to quick, quarter turn on-off operation, ball valves are compact, require no

lubrication, and give tight sealing with low torque.

If you want to know more kinds of flanged globe valves, please visit our website.

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading