Square and Rectanguilar Tubes

Specifications

Rectangular/Square hollow section are formed from coils and then ran through a series of molds. They are are welded from the inside to form their shape. Steel hollow tube is easy to cut, weld, form

and machine. Tube are designed and manufactured for mechanical and structural applications that do not require tight tolerances.

Steel Rectangular Tube Options

Height Width Wall Thickness

1/2” 1” 0.083”

3/4” 1-1/4” 0.090”

1” 1-1/2” 0.120”

1-1/2” 2” 0.180”

2” 2-1/2” 0.188”

3” 3” 0.250”

4” 4” 0.375”

5” 3/16”

6” 1/4”

8” 3/8”

11 GA

13 GA

14 GA

16 GA

18 GA

Length: According to Customer requirement.

Rectangular Steel Pipe and Square Pipe FAQs

1. What Is The Difference Between ASTM Hot Rolled & Cold Rolled Steel Tubing?

Hot rolled steel is a mill process that is performed at temperatures over 1,700°F. This process allows the steel to be easily shaped and formed into much larger sizes. Since it is processed without

delays in manufacturing, hot rolled alloy square tube is less expensive than cold rolled options.

Cold rolling increases the yield strength and hardness of a metal by introducing defects into the metal's crystal structure. Cold Rolling is most often used to decrease the thickness of the plate

and sheet metal in the manufacturing stage.

3.Is Round Or Rectangular/Square Tube Stronger?

Now the rectangular tube price is reasonable, if you have needs, please contact us.

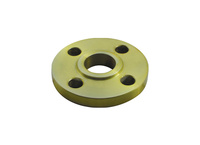

Today, Hebei Leading, as a group company, is not only manufacturing wafer butterfly valves and flanges but also is optimized to meet the needs of our customers with exceptional service and superior

quality in flow control industry, such as pipes, pipe fittings, and other kinds of valves, all of them comply with the international standards and requirements.

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading