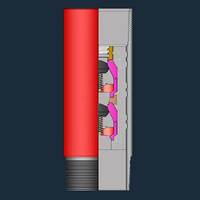

Cementing Tools

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 45days

Specifications

Cementing is an important task in the drilling process. In drilling operations, there must be at least two cementing (production wells) and up to 4 to 5 cementing (deep exploration wells). The top

cementing is the surface casing cementing, which plays the role of "mud passage, oil and gas portal". Before the next drilling, the surface casing should be equipped with a blowout preventer to

prevent blowout. A mud pipe is installed on the blowout preventer, which is a passage for the drilling fluid to return to the mud pool. In the drilling process, technical casing cementing is often

required, which plays the role of “consolidating the rear and safely exploring the road”. Like the road tunnels and the roadways in the coal mines, the wells will encounter well collapses, high

pressures and unstable formations during the drilling process. At the same time, they will also have a retreat in the case of distress in the forward "pathway" and play a "rescue". effect.

Cementing is divided into three steps: casing, cementing, wellhead installation and casing pressure test.

SAIGAO GROUP provides stage tool cementing, dv tool cementing, dv tool oilfield, dv tool drilling, dv tool oil and gas, oilfield cementing tools, etc. For more information, please feel free to

contact us!

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2008

- Address:Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

- Contact:Rex Liu

Other products from Shandong Saigao Group Corporation

Relate products of Cementing Tools

PCD Boring & Notching Tools For Carbide Rollers

描述:PCD 镗孔工具由 PCD 毛坯 (E6) 焊接在碳化钨主体上制成。最常见的是全面 PCD 开槽工具。PCD 镗孔工具用于加工各种碳化钨滚轮。用于碳化钨滚轮开槽的 PCD 刀头。 细节 规格 PCD 镗孔和开槽刀具的应用: PCD ...

Mono Crystal Diamond Tools for Ultra Precision Machining

描述:单晶金刚石刀具经磨削可获得优良的切削刃,单晶金刚石刀具表面光洁度可达 0.01微米 以上(Ra<0.1um)世界顶级原料品牌:E6单晶金刚石。 单晶金刚石工具的应用: ...