ENGINE BRACKET/ENGINE MOUNTING BRACKET

Specifications

1.Overview of car engine mounting bracket

engine bracket car which is divided into two parts is a component of automobile engine. The first one is torsional bracket, the second one is engine mounting rubber whose main function is fix the

shock absorption. Torsion bracket is a kind of engine fastener, which always connected to the engine on the front axle of the vehicle body. It is different from the ordinary engine mounting rubber

is that the mounting foot is a rubber pier directly installed in the bottom of the engine, and the torsional bracket is similar to the appearance of an iron bar installed in the side of the engine.

There is also a torsional bracket rubber on the bracket, which plays the role of damping.

2. Overview of car engine bracket

The bracket engine is the part that holds the engine in the car. In most cars, the engine and transmission are bolted together and secured together by three or four bases. Part of the car engine

bracket is bolted to the body or frame. The other part holds the engine. The mounting bracket material is a source of vibration because it has many moving and rotating parts. Car engine bracket's

job is not only to hold the engine in place, but also to reduce the engine vibration felt in the car. To further suppress vibration, some casting bracket design are filled with liquid and act as

shock absorbers. The car engine bracket does not require any maintenance or regular maintenance and needs to be replaced only in the event of failure or wear and tear.

HOW ENGINE BRACKET WORKS

The working principle of engine bracket is to fix the engine firmly on the subframe or engine base of the car. It is one of several mounts that hold the engine and transmission together and in

place. In this way, the metal surface of the engine does not friction with the metal surface of the body, allowing the shock wave to pass through the car, and rubber is used to fill the engine

bracket. Some automakers use vacuum control or electromagnetic mounting to further control vibration absorption. Problems occur when the installation material begins to deteriorate.

APPLICATION

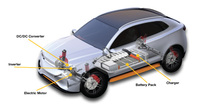

Hybrid electric vehicle

SPECIFICATION

Material A380、ADC12

Casting Process HPDC

Die Casting Machine 250-1000T

Weight Depending on part size

dimension Depending on part size

Annual Volume 60,000 per year

Porosity requirements ASTM E505 Level 3

Leakage test requirement /

Application OEM

EMP Tech, as an excellent die casting parts manufacturers, offers a wide range of aluminium parts for you to choose from.

- Country: Afghanistan

- Address: NO.38 Duanzhou San Road,Zhaoqing(526060),Guangdong,China

- Contact: Lia Gan