OEM PARTS WITH DIE CASTING

Specifications

Definition of aluminum die casting parts

Aluminum alloy die casting is a kind of pressure casting part, which uses the die casting mechanical die casting machine to install the casting mould, and pours the heated liquid aluminum alloy

into the feed port of the die casting machine. The aluminum alloy parts with limited shape and size of the die are cast by the die casting machine. Such parts are usually called aluminum alloy die

castings.

Advantages of oem casting parts

Because the metal aluminum alloy has good fluidity and plasticity.Aluminum alloy die castings can not only make a variety of complex shapes, but also have high precision and finish.The mechanical

processing of castings and the casting allowance of metal aluminum alloy are reduced, which not only saves electric power and metal materials, but also greatly saves labor costs.Aluminum alloy has

excellent thermal conductivity, low specific gravity and high processability.

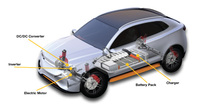

Applications of automotive parts die casting

Aluminum alloy die castings are widely used in automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission

machinery manufacturing, precision instruments, landscaping, power construction, architectural decoration and other industries.

Aluminum alloy automotive casting components can be made into aluminum die-casting automobile parts, aluminum die-casting automobile engine fittings, aluminum die-casting engine cylinder, aluminum

die-casting gasoline engine cylinder head, aluminum die-casting valve support, aluminum die-casting power accessories and other parts.

Recycling automotive aluminum die casting

There is little difference in the function of primary and secondary recycled aluminum die-casting. Secondary aluminum alloy is made of pure aluminum mixed with magnesium, iron, copper and other

materials. Due to cost, it is rarely used in pure aluminum casting. More than 95% of aluminum castings made in North America are made from recycled aluminum after consumption. The ease of use of

aluminum alloy in die casting and its lighter weight and durability make it the first choice for designers in almost all industries, for which secondary aluminum needs only 5% of energy to be

produced. Most of the energy consumption of aluminum die casting is used to heat and remelt the metal in the manufacturing process.

EMP Tech, as an excellent die-casting parts manufacturer, offers a wide range of aluminium parts for you to choose from.

- Country: Afghanistan

- Address: NO.38 Duanzhou San Road,Zhaoqing(526060),Guangdong,China

- Contact: Lia Gan