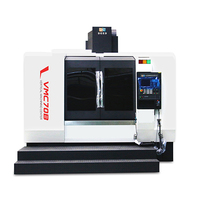

VMC 5 AXIS MACHINE

Specifications

5 axis vertical machining center is a high-end 5-axis linkage machine tool that developed after taking in the German advanced technology. VMC 5 axis machine features high efficiency, high accuracy,

high flexibility. Five axis VMC machine can continuously finish drilling, boring, reaming, tapping, and contour rough, precise machining that meets the demands of large, small box parts and many

types of flexible high efficient processing of the space surface. This five axis machining center can be widely used in aerospace, military, shipbuilding, automobile, power generation equipment. We

also provide 5 axis gantry cnc for sale. Contact us for more information!

5 AXIS VMC VERTICAL MACHINING CENTER SPECIFICATION

V650-5/V900-5/V1300-5 VMC 5 Axis Machine

VB63F5 VMC 5 Axis Machine

Other 5-axis machining center you may search for

5 axis gantry type machining center

Vertical Type DB-T Series 5-axis Machining Center

Most Required CNC Machines

CNC drill tap machine

Horizontal boring and milling center

CNC horizontal turning center

Planer type horizontal boring machine

Horizontal machining center with pallet changer

VMC 5 Axis Machine Center Benefits

1. Increased Efficiency: VMC 5 Axis Machine Centers can perform multiple operations in a single setup, which reduces the time required for machining and increases the overall efficiency of the

process.

2. Greater Precision: The ability to perform multiple machining operations in a single setup provides greater precision as there are fewer chances of errors that may occur while repositioning the

workpiece.

3. Enhanced Flexibility: VMC 5 axis machine provides greater flexibility in terms of machining complex shapes and geometries, allowing for more complex parts to be produced with greater ease.

4. Reduced Production Time: The ability to perform precise machining on a single setup, results in less time spent on setups and reduces the idle time between setups, which in turn reduces the

overall production time.

5. Improved Surface Finish: five axis VMC machine provides improved surface finish due to their ability to machine part features from multiple angles.

6. Lower Tooling Costs: The 5 axis vertical machining center requires fewer tooling changes and setups thus reducing downtime and tooling costs.

7. Reduced Scrap and Rework: The VMC 5 Axis Machine Centers are able to produce parts that meet tight tolerances which reduce scrap and the need for rework.

8. Increased Production Volume: VMC 5 Axis Machine Centers can produce high volumes of parts quickly and accurately, making them ideal for high-volume manufacturing processes.

9. Cost Savings: With reduced production time, increased efficiency, and lower tooling costs, VMC 5 Axis Machine Centers can provide cost savings in the long run.

10. Competitive Advantage: VMC 5 Axis Machine Centers provide manufacturers with a competitive advantage by producing complex parts with high precision in a shorter amount of time. This allows

companies to produce products at a lower cost while still maintaining high-quality standards.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Middle East,Americas

- Founded Year: 2008

- Address: North of Yong'an Road, Industrial Development Zone, Yanzhou District, Jining City,Shandong Province

- Contact: deed machinetool