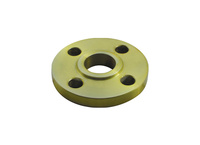

Stub End Machined Buttweld

Product Quick Detail

- FOB Price

- USD $3,000.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 3 weeks

Specifications

Stainless steel stub end is a punching method for turning over the outer edge of the rough forgings or semi-finished product. the edge is turned into a vertical edge along a certain curve. When the

edge of the stub end is a straight line, the converted deformation is converted into a curved, so it can also be said that a stub end welding method is a special form of stub end.

Stub End Machined Buttweld Dimensions

Size O.D Long Pattern Short Pattern R G

Max. Min. F F

1/2" 22.8 20.5 76 51 3 35

3/4" 28.1 25.9 76 51 3 43

1" 35 32.6 102 51 3 51

1 1/4" 43.6 41.4 102 51 5 64

1 1/2" 49.9 47.5 102 51 6 73

2" 62.4 59.5 152 64 8 92

2 1/2" 75.3 72.2 152 64 8 105

3" 91.3 88.1 152 64 10 127

3 1/2" 104 100.8 152 76 10 140

4" 116.7 113.5 152 76 11 157

5" 144.3 140.5 203 76 11 186

6" 171.3 167.5 203 89 13 216

8" 222.1 218.3 203 102 13 270

10" 277.2 272.3 254 127 13 324

12" 328 323.1 254 152 13 381

14" 359.9 354.8 305 152 13 413

16" 411 405.6 305 152 13 470

18" 462 456 305 152 13 533

20" 514 507 305 152 13 584

22" 565 558 305 152 13 641

24" 616 609 305 152 13 692

Stub End Machined Seamless/Welded VS Cap

1. Standard (Similarity):

Both stub end and cap manufacture standard can be ASME B16.9,ASME B16.28,MSS SP-43,MSS SP-75 JIS B2311,DIN2605/2615/2616/2617,GOST 17375/17376/17378/17379,ISO

2 Wall Thickness (Similarity):

Both stub end and cap wall thickness can be SCH10/10S, SCH20/the 20S, STD, SCH40/40S, XS, SCH80, XXS ETC.(for ANSI), SGP(for JIS)

3. Range of Applications (Similarity):

Size: 1/2"-48"(DN15-DN1200), or even bigger

Finishing: Polished, Pickled.

Connection type: Butt Welding

4. Installation (Difference):

One end of stub end is connected with a flange, and one end is butt welded with pipe, directly in contact with the medium.

For more information about flanged y strainer and valves, please feel free to contact us!

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading