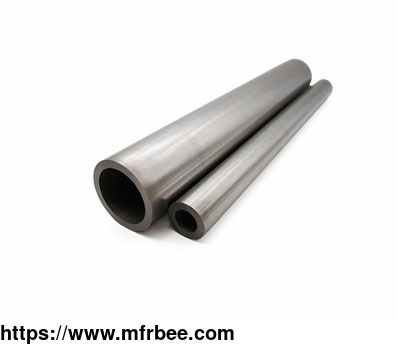

Tungsten Tube

Product Quick Detail

- FOB Price

- USD $25.00 / Piece

- Minimum Order

- 100

- Place Of Origin

- Beijing, 100079, China.

- Packaging

- Ton bag, iron barrel, wooden box

- Delivery

- 15 days

Specifications

Tungsten tube, namely pure tungsten tube, is one of the main pure tungsten products. The purity of tungsten tube produced from medium tungsten can reach more than 99.95%. Because the production

process is different, the density will be different. The density can reach 18.2g/cm3 if the product is only sintered and 19.2g/cm3 if it is fully forged. But if the size is large, such as 100mm

diameter, even after forging, can not reach 19.2g/cm3, the density can be achieved is about 18.8g/cm3.

Specification of Tungsten Tube

Grade Tungsten content Content of impurity elements

Total content Each content

W1 ≥99.95% ≤0.05% ≤0.01%

W2 ≥99.92% ≤0.08% ≤0.01%

WAL1,WAL2 ≥99.95% ≤0.05% ≤0.01%

Diameter (mm) Wall thickness (mm) Length (mm)

30-50 2–10 <600

50-100 3–15

100-150 3–15

150-200 5–20

200-300 8–20

300-400 8–30

400-450 8–30

450-500 8–30

Application of Tungsten Tube

Tungsten PIPE is mainly used in thermocouple protection tube in high temperature furnace, sapphire single crystal furnace, high temperature sintering furnace support parts and so on.

Production Process of Tungsten Tube

Tungsten tube production using powder metallurgy, after the blank, sintering, forging, polishing, inspection packaging can be shipped. China's production standard is GB/T 4187-1984, now generally

can reach the American standard ASTM F288-90.

Features of Tungsten Tube

01.

Tungsten tube has quite high purity, generally purity above 99.95%;

02.

Its density is more than 18.2g/cm3;

03.

Recommended operating temperature should be less than 2500℃;

04.

0.2965 for the tungsten tube at 2027℃;

05.

At 1600℃, the coefficient of thermal expansion is 4.98x10-6;

06.

The specific heat capacity at 1400℃ is 0.16J/ g. ℃.

07.

Tungsten tube contamination is low.

There are many tungsten tubing supplier, but we are one of the best choices for you.

For more information about types of refractory metals, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 2003

- Address: Building 13, Courtyard No. 88, Shiliu Center, Liuxiang Road, Fengtai District, Beijing, 100079, China.

- Contact: hsgmetal com