One-stop Injection Molding Service Expert

Specifications

For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to our one-stop facility. We are keen to meet your

injection molding needs with single and convenient sources. Thanks to our advanced equipment for tooling making and injection molding, Packson is able to handle all kinds of your needs of injection

molding, mold making. Despite injection molding and mold making, we also specialized in making metal machining parts by CNC machines. We are proud to offer primary, comprehensive project

management, leading-edge assembly line, product distribution, and logistics services that help you keep your company to be controlled well. Our mission has always been to assist customers to create

high-quality parts with competitive prices and fast lead time. Learn more about how you and your business can take advantage of our services today.

Explore Packson's Injection Molding Services

Are you sourcing the custom molding service supplier? Does your project need a competitive price solution? Seeking a one-stop injection moulding expert? We Packson can help you to make these come

true.

1. Project Management

At our company, we like to get involved at every stage of your product’s design. This allows us to align the manufacture of your tooling and ensure that you get the right product at the right

price. Having control from beginning to end of the production process not only keeps pricing and security tight but also reduces delays. We have a wealth of experience and knowledge servicing a

large portfolio of industries such as Electrical, Marine, Medical, Agriculture, Automotive, and Pharmaceutical. With that experience, we can de-stress the whole design and manufacturing process to

ensure that your project is delivered in a timely and professional manner.

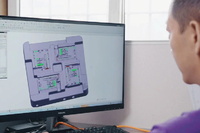

2. Design & Prototyping

At our company, we take your bespoke design or concept through CAD, prototyping and tooling to ensure you get the right product at the right price. Prototyping your new product gives you the

confidence the product design is to your expectations and verifies the design functionality.We offer two types of prototypes - SLA (Stereolithography) or SLS (Selective Laser Sintering) models

depending on your needs.

3. Tool Design & Manufacture

As a manufacturing company, we have made significant investments in state-of-the-art machinery to produce high-precision injection mould tools in-house. Our expertise lies in the creation of new

tooling, as well as modifications and adjustments to existing or transferred tooling. In addition, we provide external offshore toolmaking services, with each step meticulously project-managed and

progress documented through weekly timing plans, Gantt charts, and photographic records. As a core aspect of our service, we offer an all-encompassing tool maintenance programme, complete with

detailed work history records throughout the life of the tool at Packsonmold.

4. Quality

As a profession manufacturing company, we take great pride in our unwavering dedication to quality. All members of our team possess an NVQ certification in quality assurance, in addition to our

prestigious accreditation to ISO 9001:2015 Quality Management and Medical ISO 13485:2016. Our experienced quality department is well-equipped to identify your critical dimensions and work

collaboratively with clients to offer a range of advanced quality techniques such as APQP, FMEA, SPC, and CMM. To ensure transparency and build trust, we welcome customers and potential clients to

perform audits on our facilities.

5. Production

Our reputable company boasts an extensive range of capabilities, with a total of 40 injection machines ranging from 60-800T. Of the machines, 11 are NISSEI and 14 are LSR equipped, all located

within our state-of-the-art class 8 clean room facility. The remaining machines operate within our white room facility. Our services cater to both short-run and long-term molding production needs,

utilizing advanced techniques such as two-shot and insert molding, while adhering to rigorous scientific molding processes. We specialize in serving a variety of industries including Medical

Healthcare, Electronics, Aviation, and Toy Manufacturing, among others.

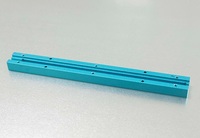

6. Secondary Operations

Our comprehensive suite of services offers a complete turn-key solution. We specialize in various secondary operations including Insert Moulding, Over-moulding, Pad Printing, Heat Staking, Foil

Block Printing, Ultra-Sonic Welding, and laser welding. Additionally, we have a specialized class 7 assembly room where we construct your mouldings in an environmentally controlled setting to meet

your unique specifications. Count on us to provide all the necessary finishing touches to your products with precision and expertise.

There are many medical molding companies, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: No.2 Building,Rongtong Industrial Park,Wulian Village,Fenggang Town,Dongguan,China

- Contact: Packson .com