Forged Round Steel Bar

Specifications

Forged round steel bar is made in cylindrical shape, which can be shaped in direct forging or re-forging into structural parts, bearings and different kinds of components and so on.

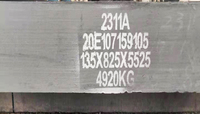

Main parameters of Forged Round Bar

Forged round bar diameter below 600mm

Common technical standards of Forged Round Bar

ASTM A29、ASTM A322、ISO683、EN10083、EN10084、EN10085、EN10250、SEW550、GB/T1591

Typical steel grades of Forged Round Bar

AISI(SAE)1018~1045 AISI(SAE)8620 AISI(SAE)8822(H) AISI(SAE)4130 AISI(SAE)4140 AISI(SAE)4150 AISI(SAE)4340 AISI(SAE)4330 AISI(SAE)6150 SA350LF3 F91 S355J2G3 16Mn(D) EH36 A105 A350LF2 Q345(B、C、D、E)

Q390(B、C、D、E) Q460(B、C、D、E) G20Cr2Ni4、GCr15SiMn、GCr18Mo, etc.

Applications of Forged Round Bar

Forged round bar are versatile products that play a vital role in various industrial applications. These products, such as forged steel round bars, are manufactured through direct forging or

re-forging to produce high-quality components, structural parts, bearings, and other crucial equipment. The inherent strength and durability of forged round bar make them ideal for use in

heavy-duty applications that require superior toughness, wear resistance, and corrosion resistance. Manufacturers of forged steel round bars adhere to the highest quality standards to ensure the

reliability and safety of the finished products. The customizable properties of forged round bar are an essential factor in their popularity in industries such as aerospace, automotive, and

construction, where specific and tailored components are essential.

Forged Round Bar Process Highlights

The process of the forging round bar is a complex and intricate one that produces high-quality forged steel round bars. This technique involves applying heat and pressure to shape and transform the

forged round bar stock into the required shape and size. The forging round bar process highlights the strength and durability of the product resulting from the forging process. Owners of forged

steel round bars can be confident in their robustness, reliable performance, and longevity due to their superior mechanical properties. The forging process also creates an improved surface finish,

which is both aesthetically pleasing and gives the product lower friction properties. The orged round bar is therefore an excellent choice for various industrial applications demanding the highest

quality components, including critical components in construction, machinery, and equipment.

There are many die steel manufacturers in China, but we are one of the best choices for you.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai