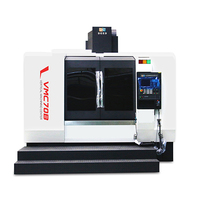

VL-SERIES VERTICAL MACHINING CENTER

Product Quick Detail

- FOB Price

- USD $30,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 1-3 months

Specifications

VL series vertical machining center is a small and medium-sized vertical machining center designed by Germany and made in China. It mainly aims at the milling of automobile aluminum hubs,

completing drilling, complex surface machining, and other processes; This product can also be applied to the processing of various kinds of parts such as plates, plates, shell parts, and molds.

After one-time clamping, the workpiece can automatically and continuously complete the processing of milling, drilling, boring, reaming, and other processes. It mainly aims at the milling of

automobile aluminum hubs, completing drilling, complex surface machining, and other vmc milling machine processes.

FEATURES OF VL-SERIES VERTICAL MACHINING CENTER

Advantages of mineral castings

1. Strong vibration absorption: the vibration absorption is 10 times that of cast iron. Under large dynamic load, the stability of machine tool accuracy is guaranteed, the machining quality of

workpiece surface is improved by 20%, and the service life of the tool is increased by 15%.

2. Excellent thermal stability: the heat conduction is 1 / 20 of that of cast iron, and the specific heat capacity is 2.1 times that of cast iron. The excellent thermal stability and thermal

inertia effectively control the deformation of the machine tool caused by temperature change and ensure the stability of the machining accuracy of the machine tool.

Moving parts - steel plate welding

1. High rigidity: The saddle, worktable, and headstock of moving parts are welded from high-strength low-alloy steel. The elastic modulus of the material is about 1.4 times that of cast iron, and

the overall rigidity of the structure is increased by 20%

2. Lightweight: Compared with cast iron, the quality is reduced by 20% - 30%, the natural frequency is increased by 10%, the possibility of resonance in the cutting process is reduced, and the

cutting stability and machining accuracy are improved.

VL-SERIES VERTICAL MACHINING CENTER SPECIFICATION

V850L

V1160L

V1370L

V1580L

V1690L

Model V850L

Spindle drive mode Belt type/direct connection type

Spindle taper BT40

Maximum spindle speed 8000rpm/10000rpm

System Spindle power(kW) 11/18.5

Spindle torque(N.M) 52.5/118

Processing Range X/Y/Z trip(mm) 850/510/510

Spindle nose to table(mm) 150-660

Workbench Workbench size (length×width) 950×500

T-slot (size×quantity×spacing) 18×4×100

Maximum load of worktable (kg) 500

Feed Rapid traverse speed (mm) 36/36/24

Precision Positioning accuracy (mm) 0.008

Repeat positioning accuracy (mm) 0.005

Tool library Tool magazine type/capacity Disc type / 24t

Maximum tool size (mm)

Full tool diameter/empty adjacent tool diameter/length Φ78/Φ150/ 300

Maximum tool weight(kg) 8

Machine weight(kg) 6000

Inquiry competitive DEED CNC vertical machining center price!

We also offer the following vertical machining centers and tools

VMC-series Vertical Machining Center: VMC vertical machining center

GV-series Vertical Machining Center

As a CNC machining center factory, Shandong DEED Precision Machine Tool Co., Ltd. was founded in 2017, based in Yanzhou District, Jining City, Shandong Province, with a registered capital of 220

million yuan, an area of 200 hectares, and more than 400 employees.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Europe,Middle East,Americas

- Founded Year: 2008

- Address: North of Yong'an Road, Industrial Development Zone, Yanzhou District, Jining City,Shandong Province

- Contact: deed machinetool