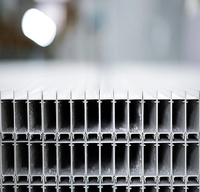

Custom Mirror Surface Profiles

Specifications

Custom mirror frame profiles are used in applications where a reflective surface is desired for aesthetic or functional purposes. These profiles are commonly used in decorative applications, such

as furniture, retail displays, and architectural elements, as well as in high-performance applications, such as automotive and aerospace components. Custom mirror surface profiles may be created

using a variety of methods, such as electroplating, vacuum-metalizing, and baking paint appearance parts series. The type of mirror surface profile used will depend on the specific application

requirements, such as the desired level of reflectivity, durability, and resistance to wear and corrosion. Custom mirror profiles offer improved aesthetics, durability, and functionality.

What Are The Advantages Of Using Mirror Surface Profiles?

Increased Durability

By creating a smooth and polished surface, mirror surface profiles can increase the durability and longevity of materials. This is particularly true for metals and plastics, which can become prone

to corrosion and breakage when surface imperfections are present.

Resistance To Corrosion And Weathering

The removal of surface imperfections through mirror surface profiling reduces the number of areas where moisture, dirt, and other contaminants can become trapped, which can lead to corrosion and

weathering over time.

Improved Aesthetic Appeal

Mirror surface profiles create a visually stunning finish that reflects light in a way that highlights the details and texture of the material being worked with. This is particularly beneficial for

high-end consumer products, where aesthetic appeal is a key feature.

Improved Visibility

Mirror surface profiles can be used to create surfaces that are highly reflective, which can be helpful in situations where visibility is important. For example, mirrors and reflective surfaces are

commonly used in car mirrors, medical tools, and optical components.

How Are Mirror Surface Profiles Created?

Mirror surface profiles are created using a variety of techniques that aim to remove microscopic imperfections from the surface of a material to create a smooth and reflective finish. Here are some

common methods used to create mirror surface profiles:

1. Polishing: In this process, a polishing wheel is used along with an abrasive compound such as cerium oxide to smooth out the surface of the material. This method is commonly used for metals such

as aluminum, brass, and stainless steel.

2. Grinding: This process involves using a grinding wheel to remove any surface imperfections or uneven areas on the material. A series of finer grit grinding wheels are used to gradually polish

and smooth out the surface as well.

3. Buffing: This process uses a mounted buffing wheel with a soft polishing compound such as wax or rouge to create a smooth, shiny finish on the material. This method is commonly used to polish

plastics, glass and certain types of metals.

4. Electro-polishing: This is an electrochemical process that uses an electric current to remove a thin layer of surface material in order to create a shiny, mirror-like finish. It is often used on

metals including stainless steel, titanium, and aluminum.

There are many extruded profile suppliers, but we are one of the best choices for you.

- Country: China (Mainland)

- Founded Year: 2017

- Address: No.28 Rongtang Road,Yuqi Town,Huishan District

- Contact: huayuplas com