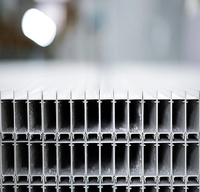

General Plastic Extrusion Profiles

Product Quick Detail

- Minimum Order

- 2000

- Place Of Origin

- Wuxi, Jiangsu, China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

A die or group of dies are used to heat raw plastic material during the plastic extrusion molding process and shape it into a continuous profile or length. Flexible plastic goods called general

profile extrusion plastic are employed in a wide range of tasks like sealing, edging, decorating, and reinforcing. These extruded plastic profiles from plastic profile manufacturer are frequently

constructed from popular plastic materials like PVC, PE, PP, or ABS, and they come in a variety of forms including tubes, channels, rods, strips, and sheets. Because to their great strength,

endurance, and resistance to chemicals and the elements, they offer a practical and affordable option for a variety of sectors.

Types of General Plastic Extrusion Profiles

Custom ABS Extrusions Plastic Profile

ABS extrusions profile, known for its strength and impact resistance, is widely used in the construction and automotive industries.

Custom PP/PE Extrusion Profile

PP (polypropylene) and PE (polyethylene) extrusion profiles are highly durable and chemical-resistant, making them ideal for the packaging, storage, and transportation industries. These profiles

can be customized to meet specific project requirements and come in a variety of shapes, such as tubes, channels, rods, strips, and sheets. Overall, general plastic extrusion profiles offer

versatile solutions for many applications in various industries.

Stock Extruded Plastic Industry Profiles

Huayu, your premier destination for top-quality stock extruded plastic profiles. As one of the leading extruded plastic profile suppliers, we provide a diverse range of plastic extrusion profiles

and shapes to meet various industry needs. Our stock extruded plastic profiles offer exceptional strength, durability, and affordability. Explore our wide selection of plastic extrusion shapes

and find the perfect fit for your requirements. Trust Huayu to deliver reliable and high-performance stock extruded plastic profiles for your projects.

How General Profile Plastic Extrusions Are Made?

Raw plastic material is heated and shaped into an uninterrupted profile or length during the profile custom extrusion process. Plastic powder or pellets are first melted, then fed into a barrel

where they are pushed at a high pressure through a die or series of dies. A water bath or other cooling system is used to drive plastic material through a die that has been molded to the required

profile. The material is then trimmed to the required length and form after being extruded. For usage in several applications across numerous sectors, extrusion profiles may be made in a range of

forms and sizes.

What Are The Profile Shapes Of Plastics?

Discover the diverse world of plastic profile shapes at Huayu. Our range includes the popular U-shaped plastic profiles as well as a variety of other extruded plastic shapes. Engineered to meet

industry standards, our plastic extrusion profiles offer superior strength and durability. Whether for architectural or industrial applications, our profiles are expertly crafted to suit your

specific needs. Explore our collection and find the perfect plastic profile shape for your project.

- Country: China (Mainland)

- Founded Year: 2017

- Address: No.28 Rongtang Road,Yuqi Town,Huishan District

- Contact: huayuplas com