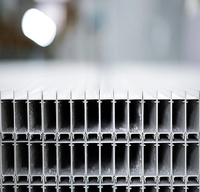

Engineering Plastic Extrusion Profiles

Product Quick Detail

- Minimum Order

- 2000

- Place Of Origin

- Wuxi, Jiangsu, China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Engineering custom plastic extrusion profiles are made from several technical polymers, each of which has special qualities including high elasticity, high wear and tear resistance, and great

chemical resistance. Together with these qualities, the material manufactured by plastic extrusion manufacturers also has great machinability, dimensional stability, and resilience to high

temperatures. These extrusion profiles provide solutions for sealing, electrical and thermal insulation, structural components, fluid management, and other high-performance applications. They are

utilized in a variety of sectors, including automotive, aerospace, medical, and industrial. Extrusion profiles made of engineering plastics provide a number of benefits over materials like metal,

rubber, and wood in terms of versatility, cost, and other factors.

Types of Engineering Custom Plastic Extrusion Profiles

Custom Nylon Profile

nylon is a tough and durable plastic material, known for its high resistance to wear and tear. Nylon extrusion profiles are commonly used in industries such as automotive, industrial, and

construction.

Custom Elastomer Profile

elastomer materials offer high elasticity and flexibility, making them ideal for sealing or vibration damping applications.

Custom PC Extrusions Profile

polycarbonate provides high transparency, good impact resistance, and is commonly used in optical-grade applications such as lenses and windows.

Custom Enhancement GF Extrusion Profile

glass fiber is a material that can be added to plastic to provide reinforcement and increase strength, stiffness, and temperature resistance.

Other Custom Plastic Extrusion Profiles

there are several other engineering plastic materials available for extrusion profiles, including acetal, PEEK, PTFE, and PET, among others.

Other Custom Plastic Extrusion Profiles

Advantages of Using Engineering Plastic Extrusion Profiles in Packaging and Storage

Plastic extrusion profiles offer several advantages for packaging and storage applications, including durability, chemical resistance, flexibility, and customization. These custom extruded profiles

can be designed to fit specific product requirements, and their lightweight nature also makes them ideal for transport and storage. Additionally, extrusion profiles can be produced in high volumes,

reducing costs and inventory management issues by plastic profile extrusion companies. Their ability to be recycled also makes them an environmentally-friendly choice. Overall, plastic extrusion

profiles provide cost-effective and versatile solutions for various packaging and storage requirements.

Properties of Plastic Materials Used in Engineering Plastic Extrusion Profiles

Extrusion profiles are produced using a variety of plastic materials, each with special characteristics for a range of applications. PVC, as an illustration, has good weatherability and flame

resistance. The hardness and impact resistance of ABS are well recognized, but the high transparency and impact resistance of polycarbonate are. Due to its high level of durability and chemical

resistance, polypropylene is perfect for storing and packaging applications. Excellent toughness and low-temperature resistance are features of PE. The characteristics and applicability of

extrusion profiles for various purposes are largely dependent on the type of plastic material employed.

- Country: China (Mainland)

- Founded Year: 2017

- Address: No.28 Rongtang Road,Yuqi Town,Huishan District

- Contact: huayuplas com