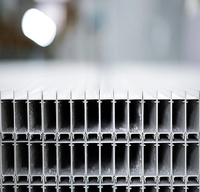

Custom Nylon Profile

Specifications

Extruding unique goods out of nylon material is called nylon profile extrusion. Nylon is a robust and long-lasting thermoplastic material that is resistant to abrasion, heat, and chemicals, making

it ideal for a variety of applications including automobile parts, electrical components, and medical equipment. Customized forms, sizes, and colors may be produced using nylon profile extrusion to

satisfy the needs of the customer. For consumers looking for high-quality, dependable, and long-lasting products, nylon material's adaptability makes it a great option.

What Are the Advantages of nylon extrusion profiles?

Strength and Durability

Nylon has a high strength-to-weight ratio and excellent durability, making it an ideal material for making strong and tough products. It is also resistant to stains, fungus, and mildew. Nylon is

widely used in industrial applications because it can withstand impact, abrasion, and wear and tear.

Chemical Resistance

Nylon has excellent resistance to a broad spectrum of chemicals, including alkaline solutions, oils, fuels, and most organic solvents. Its resistance to chemicals and moisture makes it ideal for

use in tubing, seals, and other components that require resistance against environmental factors. The chemical resistance of nylon is further improved by its ability to withstand high temperatures.

Versatility

Nylon is a highly versatile material that can be formed into various shapes and sizes. Its toughness and ability to retain its shape of use make it ideal for use in a range of applications. It can

be extruded, molded or shaped into fibers, films, and other products with relative ease. Nylon is widely used in different industries such as automotive, consumer products, and the textile

industry.

Electrical Properties

Nylon has excellent electrical properties, making it ideal for electrical insulation applications. Nylon has excellent resistivity and can sustain high voltage. Its ability to resist electrical

current is an essential characteristic that makes it a preferred material in electronic component production.

What Is the Applications of Nylon Profile?

1. Automotive Parts: Nylon profiles are used in the manufacturing of automotive parts such as gears, bearings, bushings, and other structural components in vehicles.

2. Electrical Components: Nylon profiles are used to manufacture electrical components such as cable ties, insulators, connectors, and switches.

3. Medical Equipment: Nylon profiles are used in the production of medical equipment such as prosthetics, catheters, and surgical instruments.

4. Industrial Machinery: Nylon profiles are used in the manufacturing of industrial machinery such as conveyor belts, rollers, and gears.

5. Aerospace: Nylon profiles are used in the aerospace industry for the production of structural components, fasteners, and hydraulic systems.

6. Marine Industry: Nylon profiles are used in the marine industry for the production of boat parts such as propellers, bearings, and steering systems.

7. Construction: Nylon profiles are used in the construction of buildings for the production of curtain walls, façade systems, and cladding components.

If you are looking for a reliable extruded profile company, don't hesitate to contact us!

- Country: China (Mainland)

- Founded Year: 2017

- Address: No.28 Rongtang Road,Yuqi Town,Huishan District

- Contact: huayuplas com