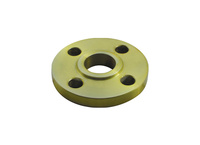

ZHMWS-A1 WCB Body Check Valves Flanged End

Specifications

Cast Steel Swing wcb check valve bonnet bolts, univalve swing, is the international swing check valve structure. Steel flanged check valves function of the control valve is a unidirectional flow of

the medium in the pipeline, to prevent the line of medium back.

ZHMWS-A1 WCB Body Check Valves Flanged End Dimensions

WCB Body Check Valves Flanged End VS DI Body

1. Standard:

WCB body check valves manufacture standard is API 6D,ASME B16.34,DIN3202,BS1868,JIS B2071. DI body check valves flanged end manufacture standard is MSS SP-71,DIN3202,BS5153,JIS B2031.

2. Pressure (Similarity):

WCB body check valves pressure can be Class 150/300/600/900, PN10/16/25/40/63,5K/10K/16K, D.I.body check valves pressure is Class125/150, PN10/16,5K/10K16K.

3. Range of Applications (Similarity):

Stardard: DIN 3202 PN10/16, ANSI CLASS 125/150

Face to face: DIN 3202 F1, MSS-SP-85

Connection flange type: Flange end

4. Installation (Difference):

WCB body check valves have higher strength, plasticity, and toughness than DI body check valves, more suitable for higher pressures and lower or higher temperature fluid systems.

ZHMWS-A1 WCB Body Check Valves Flanged End FAQs

1. What is a Check Valve?

A check valve refers to a valve whose opening and closing parts are circular discs and rely on its own weight and medium pressure to block the backflow of the medium.

2. How Do Swing Check Valves Work?

The swing check valve is automatically opened and closed by the force generated by the flow of the medium itself in the pipeline. It belongs to an automatic valve. The function of the swing check

valve is to prevent the medium in the pipeline from flowing back. Check valves belong to the category of automatic valves, and the opening and closing parts are opened or closed by the force of the

flowing medium. The check valve is only used in the pipeline where the medium flows in one direction to prevent the medium from returning to prevent accidents.

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading