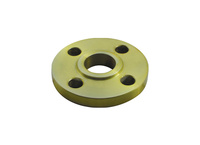

ZMSO-D1 Stainless Steel Flanged Gate Valves

Specifications

Stainless Steel Gate valve Features

Small flow resistance. Because the internal medium channel of the valve body is straight-through, the medium is flowing straight, so the flow resistance encounters is small.

In order to make a reliable valve seal, it is reasonable to use the sealing surface and the packing seal design

Because of the long stainless steel valve closing time, the water hammer phenomenon less likely to occur

Simple in shape, short face to face length, good manufacturing process, wide applicable

Compact structure, rigid valve, it is a product with a smooth channel

ZMSO-D1 Stainless Steel Flanged Gate Valves Dimensions

Stainless Steel Flanged Gate Valves VS WCB Gate Valves

1. Standard:

Both stainless steel flanged gate valves and WCB body gate valve manufacture standard is API 6D, API600, ASME B16.34, DIN3352, BS1414, JIS B2071

2. Pressure:

Both stainless steel flanged gate foot valves and WCB body gate valve pressure can be Class150/300/600/900, PN10/16/25/40/63,5K/10K/16K

3. Range of Applications (Similarity and Difference):

Standard: BS, DIN, ANSI

Face to face:DIN3202 F4/F5, ANSI B16.10

Connection flange type: Flange end

4. Installation (Difference):

Stainless Steel Flanged Gate Valves are more resistant to corrosion and oxidation than WCB gate valves, which are more suitable for acid and alkaline media.

ZMSO-D1 Stainless Steel Flanged Gate Valves FAQs

What Materials Are Available for Stainless Steel Flanged Gate Valves?

SS304, SS316

Where Should Stainless Steel Gate Valves Used?

Stainless steel gate valves are usually used in corrosive, high- and low-temperature service.

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading