GYTC8S / GYXTC8S Fiber Optic Cable

Specifications

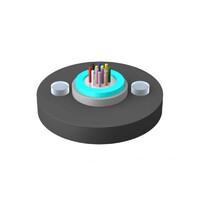

The cross-section of GYTC8S Cable's is in the shape of "8". The steel strand is suspended, and the double-sided plastic-coated corrugated steel belt forms excellent flattening resistance. With

self-supporting overhead steel strand, much installation time and cost is saved.

As one of the professional optical fibre manufacturing companies, TUOLIMA has been manufacturing fiber optic cable including gytc8s or gyxtc8s cable for over 10 years with ISO, UL, RoHS, REACH

certificates. The reliable quality of TUOLIMA products has won its popularity across five continents and the spread is growing. You can check the details of our GYTC8S / GYXTC8S Fiber Optic Cable

on this page. Or you can consult us directly, if you have any questions about TUOLIMA GYTC8S / GYXTC8S Fiber Optic Cable.

Details of GYTC8S&GYXTC8S Fiber Optical Cable

The structure of the standard figure-eight self-supporting stranded optical cable is that multimode or single mode fiber optic cables are sheathed in a loose tube made of high modulus plastic, and

the tube is filled with a water blocking compound. The center of the cable core is a metal reinforced core. For certain fiber optic cables, a layer of polyethylene needs to be squeezed outside the

metal-reinforced core. The loose tube (and filler rope) is twisted around the central reinforced core to form a compact and Round cable core, the gap in the cable core is filled with water blocking

filler. The cable core is longitudinally wrapped with steel-plastic composite tape, and placed in parallel with the steel strands while extruding a figure-eight sheath into a cable.

Item Description

Fiber counts of cable 8

Loose tube Material PBT

No. fiber per tube 8

No. of tube 1

Diameter(mm) Nom. 2.0

Filling compound Material Thixotropic jelly

Suspension wire Material Metallic strengthen member

Diameter 1.0mm*7

Approx. cable dia.(mm) Approx.8.3

Approx. overall(mm) Approx.15.8

Max. Tensile strength(N) 3000

Crush Resistance (N/100mm) 7990

Operating Temperature(℃) 0 ~ +60

Characteristics of GYTC8S&GYXTC8S Fiber Optical Cable

Optical fiber characteristics (G.652D FIBER)

Description Specifications

Category Before cabling After cabling

Optical Specifications Attenuation @1550 nm ≤0.20 dB/km (max.) ≤0.22 dB/km (max.)

Attenuation @1625 nm ≤0.23dB/km ≤ 0.24 dB/km

Zero Dispersion Wavelength ≤1520 nm

Zero Dispersion Slope ≤ 0.084 ps/nm2·km

Polarization Mode Dispersion(PMD) ≤0.08 ps/km

Cable Cutoff Wavelength (λcc) ≤1450 nm

Macro bending Loss ≤ 0.05 dB

(1 turn; Ф32 mm) @1550 nm ≤ 0.05 dB

(100 turns; Ф60 mm) @1625 nm ≤0.05 dB

(100 turns; Ф50 mm) @1310 &@1625 nm

Mode Field Diameter @1550 nm 9.6±0.5μm

Dimensional Cladding Diameter 124.8 ±0.7μm

Specifications Core/clad concentricity error ≤0.6μm

Cladding Non-Circularity ≤1.0%

Mechanical Min bending radius 12.5D (static) 25D (dynamic)

Specifications Proof Test level ≥1.2%

Fiber Curl Radius ≥4.0m

Peak Coating Strip Force 0.9~6.8N

Specification of GYTC8S / GYXTC8S Fiber Optic Cable

No Item Test standard Method Acceptance criteria

1 Tensile IEC-60794-1-E1 Max. Tensile strength -Fiber strain at maximum

test Sample length:50 meters Load: max. 0.33%

Time: 1minutes; -Attenuation increase≤0.10dB

2 Crush IEC-60794-1-E3 Load:1000N -No splits or cracks in the

test Time: 1 minutes outer jacket;

Length: 100mm -Attenuation increase<0.10dB,

3 Impact IEC-60794-1-E4 Impact energy: 450g -No splits or cracks in the outer jacket

test Height:1 meter -Attenuation increase≤0.10dB

Impact points: min.1

Number of impacts: 5

4 Repeated bending IEC-60794-1-E6 R=20×cable outer diameter - No splits or cracks in the outer jacket

1m cable length with 150N weight,30 cycles -Attenuation increase ≤0.10dB

5 Torsion IEC-60794-1-E7 1m cable length with 150N weight - No splits or cracks in the outer jacket

test ±180 degrees, 10 cycles -Attenuation increase ≤0.10B

6 Bending IEC-60794-1-E11 Diameter of mandrel: 20×D - No splits or cracks in the outer jacket

test Number of turns/helix:10 - No fiber break

Number of cycles: 5

7 Temperature cycling test IEC-60794-1-F1 Temperature step: +20℃→0℃→+60℃→0℃→ -Attenuation variation for reference value(the attenuation to be measured before test at +20±3℃) ≤0.10dB,

+60℃→+20℃

Time per each step: 12 hrs

Number of cycles: 2 cycles

8 Water penetration test IEC-60794-1-F5 Water height: 1m -No water leakage at the end of the sample

Sample length:3m

Duration of test: 24hrs

9 Drip test IEC-60794-1-E14 Five 0.3m samples suspended vertically in a climate chamber, raised temperature to +70℃ -No filling compound shall drip from tubes after 24 hr

Advantages of GYTC8S / GYXTC8S Fiber Optic Cable

Use high-quality optical fiber to ensure that the optical cable has excellent transmission performance

Accurately control the excess length of the outdoor fiber optic cable to ensure that the optical cable has excellent mechanical and high/low-temperature characteristics

Full-section water-blocking structure to ensure good water-blocking and moisture-proof performance

The loose tube is filled with special grease to protect the optical fiber critically

The longitudinally clad steel tape strengthens the resistance to lateral pressure of the optical cable

Packing and Comments of GYTC8S/GYXTC8S Fiber Optic Cable

Packing material: Non-returnable wooden drum.

Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture.

Cable printing: The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

Cable type and number of optical fiber

Manufacturer name

Month and Year of Manufacture

Cable length

Drum marking: Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

Manufacture name and logo

Cable length

Cable type and number of fibers

Roll way

Gross and net weight

- Country: China (Mainland)

- Founded Year: 2003.12

- Address: Add.: Qianjiang Science Technique Mansion, No.388 Wensan Road, Xihu District,Hangzhou 310012,Zhejiang, China

- Contact: Cntuolima com