Brominated Butyl Rubber

Specifications

Brominated Butyl Rubber

Bromo butyl rubber BIIR is a copolymer rubber of bromo isobutylene and isoprene. It is derived from halogenating butyl rubber with bromine in a continuous process. Bromo butyl rubber products

possesse other fundamental advantages including stability at high temperatures, rejuvenating capabilities, stronger resistance, increased adhesion to other rubbers and metals, and lastly, improved

ozone and environmental resistance.

Specification of Brominated Butyl Rubber

Grades Unit 2302 2402 2502

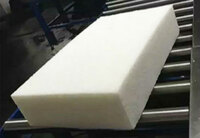

Appearance / White or Amber Bales

Density g/cm³ 0.93

Mooney Viscosity MU 32±5 39±5 46±5

ML(1+8)125℃

Volatiles WT% ≤0.7

Antioxidant WT% Non-staining ≥0.02

Bromine Content WT% 2.1±0.2

Total Ash Content WT% ≤0.7

Stabilizer Content WT% 1.3±0.3

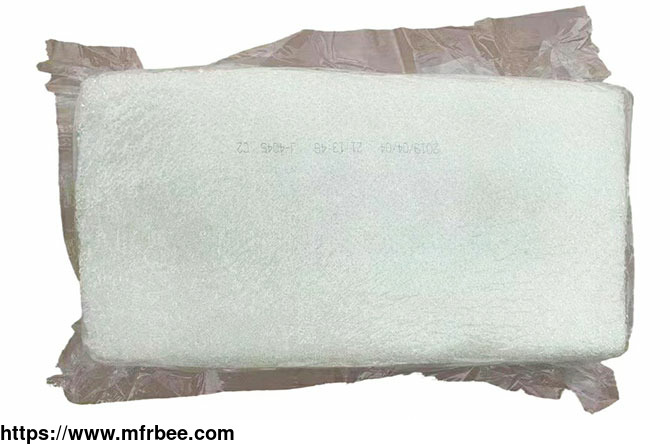

Packing of Brominated Butyl Rubber

25±0.5kg/bale in EVA film or modified PE film.

Pallets of plywood box of 1050kg with 42 bales.

Pallets of metal box of 1200kg with 48bales.

Application of Brominated Butyl Rubber

Bromo butyl rubber BIIR has superior air impermeability, outstanding performance of heat-resistance, chemical corrosion-resistance, thermal aging resistance, and good curing performance. It can be

widely used for tire inner liners, medical stoppers, corrosion-resistance lining, protective clothing, shoes production and TPV industry.

As a rubber raw materials company, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Address: 6F Dong Sheng Plaza, Wei Fang City, Shan Dong Province, China.

- Contact: YU SHENG