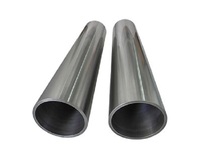

Tantalum Tube

Specifications

Seamless tubes are made by extruding, reducing the size of the tubes, or deep drawing with sheet metal. The manufacturing method of welding is first formed strip, and then made into a tube, and

then the joint with gas tungsten arc (GTAW) welding.

Specification of Tantalum Tube

Application of Tantalum Pipe

The heating parts and heat insulation in vacuum blast furnace

Aerospace avition industry

Cookers, coolers, various utensils and devices in the chemical industry

Medical equipment

Application of Tantalum Tube

Production Process of Tantalum Tube

Tantalum tube pipe has a variety of processing methods, the pipe varieties have extrusion tube, rolling pipe, stretching, number of spinning tube, and welded tube.Bad preparation methods mainly

include tantalum tube extrusion, strip and plate welding plate spinning, etc.; Finished pipe rolling, stretching and main production methods Spinning.

If you are looking for a reliable refractory metal company, please choose us, and we will be your best partner.

- Country: China (Mainland)

- Founded Year: 2003

- Address: Building 13, Courtyard No. 88, Shiliu Center, Liuxiang Road, Fengtai District, Beijing, 100079, China.

- Contact: hsgmetal com