Tube Mill

Specifications

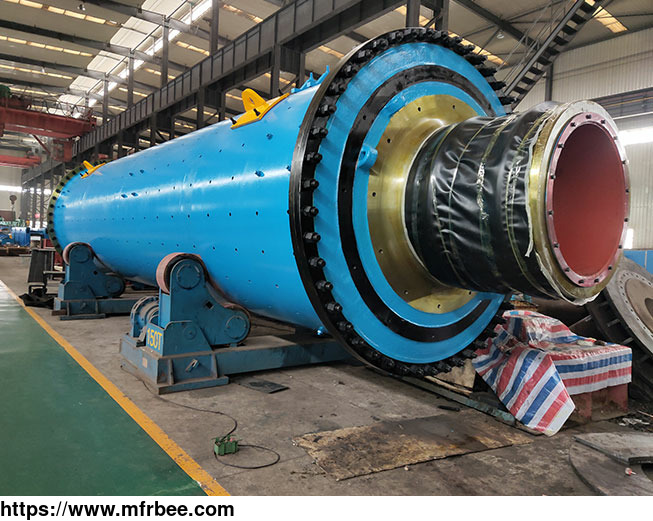

Tube Mill

Tube mill is one of CIC grinding mill product series. The ball tube mill is mainly used for grinding finished products and raw materials in cement plants. It is also suitable for grinding various

ores and other grindable materials in metallurgical, chemical, electric power and other industrial and mining enterprises. The steel tube mill machine manufactured by CIC has the characteristics of

strong adaptability to materials, continuous production, large crushing ratio and easy to adjust the fineness of grinding products. It can be produced by dry method, wet method, grinding and drying

at the same time.

Introduction of Ball Tube Mill

The ball tube mill is a very important fine industrial grinding mill in modern industry, and the production capacity of a large tube mill is very high. The difference between a single bin tube mill

and a short cylinder cement ball mill is that a single bin tube’s length is 2-7 times larger than its diameter, the material experiences a long time in the tube mill machine, the product fineness

is uniform and the crushing is relatively large. In fact, a multi-bin tube mill is more widely used than a single bin mill. In the multi-bin tube mill, the partition plate separates the mill

cylinder into several bins. In each bin, it cooperates with the grinding body according to the fine grinding of materials, so that the fine grinding of materials can be carried out by stage, so as

to reach high grinding efficiency and large unit power output. Tube mill machine is widely used for grinding cement and other materials in building materials, metallurgy, mineral processing,

electric power and chemical industries. Among all ball mill grinding machine, The tube mill has the characteristics of a large crushing ratio, large production capacity, strong adaptability to

materials and easy replacement of spare parts. The main components of the tube mill are the cylinder, feeding part, unloading part, transmission part, etc.

Advantage of Tube Mill Machine

Tube mill machine has strong adaptability to the fluctuation of material physical properties (such as particle size, moisture, hardness, etc.) and a large production capacity.

Large crushing ratio, (generally more than 300, more than 1000 for ultra-fine grinding), the fineness of the product is fine, and the particle gradation is easy to adjust.

It can adapt to different operations: dry operation or wet operation, and the two processes of drying and grinding can be combined for simultaneous operation; It can be ground in an open circuit or

closed circuit.

Good sealing can be operated under negative pressure, and there is no dust flying in the workplace.

It is convenient for large-scale production and can meet the needs of large-scale production of modern enterprises.

Structure of Tube Mill

The tube mill has a long barrel so that the material can be ground in the mill for a long time. Therefore, the tube mill is suitable for the fine grinding of materials. The tube mill shown in

Figure 1 is a central transmission, central discharge and three bin tube mill. The discharge end cover 1 is connected with the transmission connecting pipe 2 with a discharge hole. There are grid

plate 3, lifting plate 4 and discharge screw 5 at the discharge end. The direction of the helix is the same as that of the mill, and a cylindrical screen 6 is installed on the transmission

connecting pipe. A vibrating device is installed on the screen to prevent the screen hole from being blocked. These devices are sealed in the discharge narrow 7. The upper part of the discharge

cover is pushed to the dust collector with a pipeline, and the lower part is passed through the finished product conveying equipment. The transmission connecting pipe 2 extends from the discharge

end and forms a transmission system with the reducer and motor. The reducer is also equipped with a slow drive device, which can be used to turn the access door on the cylinder to the required

position at any time during maintenance, and when starting the mill.

In the tube mill with a multi-chamber, the first chamber is used for rough grinding. The grinding of materials by the medium in the warehouse is mainly impacted. The later chamber is used for fine

grinding. The grinding of materials by the medium in the chamber is mainly stripping grinding, so the diameter of the medium is also small. Fig. 2 is a cross-section of the tube mill cylinder. In

order to meet the grinding requirements, the lining form of each bin should also be properly selected. Generally, the stepped lining plate 3 is laid in storehouses I and II; Lay corrugated lining

plate 4 in chamber III. The length of the compartment can be completed by adjusting the position of the compartment plate. As can be seen from Fig. 2, the compartment plates between compartments I

and II are integral; The compartment plates between compartments II and III are combined.

Intelligent Grinding Expert System-Tube Mill

To realize the intelligent control for grinding mill operation, we provide the intelligent grinding expert system. It will monitor the situation of the tube mill working and the finished products'

status.

Service for Tube Bill

We do not just make machines but design, produce, run trial tests, and provide services after delivery. By joining your planning process, we meet your request totally. We have unique skills that

other companies can't compete with.

Tube mill we produced for the EPC of environmental protection project. This is the construction crew on-site installation.

Packaging and Delivery

Packaging and delivery is the last step for our mill to leave the factory. Although the production process has been completed, if the final packaging and delivery are not done properly, the work

will fall short. CIC uses sophisticated, rigorous packaging to ensure that the mill and its spare parts reach our customers in an intact situation through the harsh offshore conditions. It is

CIC's consistent service standard to do every detail well, including packing and shipping.

Spare Parts & Service of Tube Mill

Supporting Spare Parts Service

As a manufacturer of complete sets of equipment, CIC will also provide you with follow-up supporting services. Supporting mill spare parts update and replacement services, such as mill shell

reconstruction, end cover and liner replacement, will enable your equipment to run for a long time, reduce costs, improve efficiency.

Mill Liners

CIC has liner factory with the scope of business from selection and design, research and test to manufacture, which can not only provide supporting liner production and processing services for our

own grinding mill but also provide liner replacement and transformation services for all kinds of mill specifications and models.

Professional Service

CIC can provide a new upgrade service for your grinding mill so that your equipment can increase production capacity and output, and reduce downtime and maintenance. CIC has a unique mill

intelligent control system, which can improve the overall safety, realize the modern controls and automation, and reduce human intervention and risk exposure.

- Country: China (Mainland)

- Address: 99 Hengshan Road, Jianxi District, Luoyang, Henan, China

- Contact: cice mech