SKLN Counterflow Cooler

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

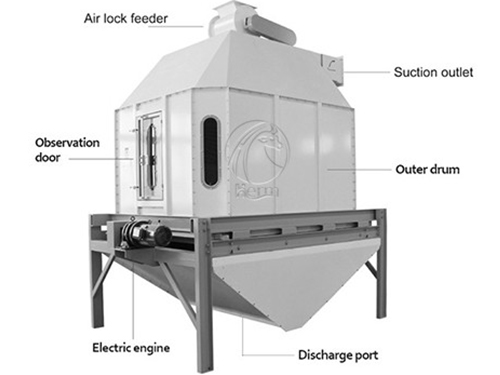

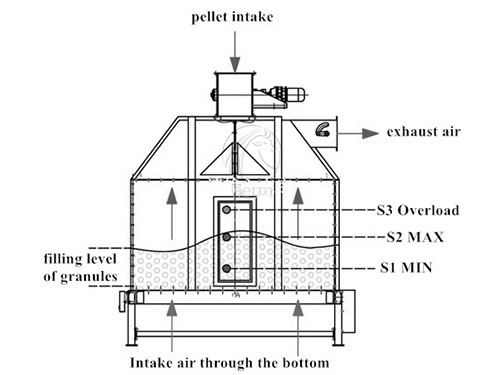

SKLN Counterflow Cooler Introduction

The cooling of pellets is an indispensable process in the granulation section. Our SKLN serious counterflow cooler is adopted to cool the pellets with high temperature and moisture. Hot air touches hot pellets and cool air touches cool pellets to avoid the pellet surface crack caused by sudden cooling produced by direct touching between cool air and hot pellets. The counterflow cooler can cool the pellets with a temperature of 70 ℃ -90 ℃ to a temperature slightly higher than the room temperature of 3 ℃ -5 ℃, and can be reduced to safe moisture (≤12.5%), which is convenient for pellet transportation and storage. The machine adopts a unique sliding valve mechanism to discharge materials, and the operation is smooth and the discharge is smooth.

SKLN Counterflow Cooler Advantages

Uniform cooling

It is widely used in the feed and biomass processing industry to cool various granular materials.

Small footprint

The vertical overall layout, compact structure, and small footprint.

Easy to maintain

There is an inspection door on the front of the equipment, observation windows on the side, and a top cover, which are convenient for observation and inspection.

Long-lasting

The discharge pressure relief plate increases the working load, reduces deformation, and prolongs the life of parts.

Stable operation

The geared motor drives the eccentric shaft for transmission, which is stable and reliable, with low noise and easy installation and maintenance.

Unique design

The octagonal cooling bin prevents dead ends.

- Country: China (Mainland)

- Business Type: Henan Herm Machinery Co., Ltd.,Manufacturer

- Market: Africa,Middle East

- Founded Year: 2010

- Address: No.50 Futing Road, Fugou Industrial Park,Fugou County

- Contact: Merry Zhang