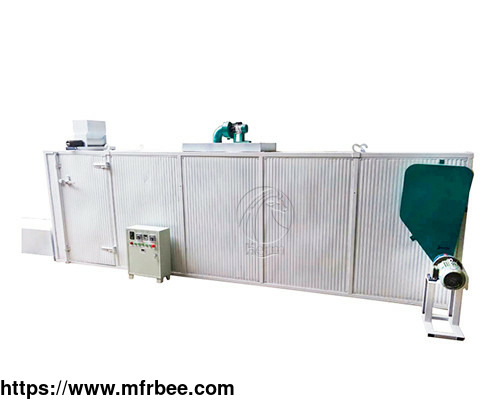

Convection Belt Dryer

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Multi-Pass Convection Belt Dryer Introduction

Our premium multi-pass convection belt dryers are suitable for drying products such as extruded feed, pet food, and grain products. The material is evenly distributed in the sieve, and the drying uniformity is good. The material is still relative to the sieve, and moves forward with the sieve, effectively reducing the grinding rate. The drying time can be adjusted according to specific requirements. Suitable for cattle feed pellet production line, pig feed pellet production line, sheep feed pellet production line, chicken feed pellet production line, forestry waste pellet production line, organic waste pellet production line, agricultural waste pellet production line, etc.

Multi-Pass Convection Belt Dryer Applications

The multi-pass convection belt dryer is mainly used for drying food and extruded feed. The material is evenly distributed in the sieve, and the drying uniformity is good. The material is still relative to the sieve, and moves forward with the sieve, effectively reducing the grinding rate. The drying time can be adjusted according to specific requirements.

Multi-Pass Convection Belt Dryer Working Principle

The pure hot air generated by the hot blast stove can control the temperature of the hot air from 50°C to 160°C. Two drying and dehydration methods are adopted: heating drying and ventilating drying. The hot air ventilation volume is adjusted reasonably. Drying, making full use of hot air, drying quickly and efficiently.

Multi-Pass Convection Belt Dryer Advantages

1. High efficiency

Multi-layer material drying makes full use of space and greatly improves drying efficiency. At the same time, part of the waste heat is recovered to improve thermal efficiency.

2. Low energy consumption

The area of each drying zone can be adjusted flexibly to improve heat transfer efficiency.

3. Environmental Protection and Hygiene

Smooth surfaces are used inside to reduce dust accumulation.

4. Easy to maintenance

The inlet part adopts a non-welding assembly, which is convenient to enter the dryer for maintenance and repair.

5. Main application

It is suitable for drying treatment of extruded feed, pet food, grain products, and other products.

6. Flexible control

The drying temperature, material residence time, and fluid bed depth are adjustable, and the quality control is flexible.

7. Stable operation

The horizontal belt conveyor runs smoothly with a low breakage rate.

- Country: China (Mainland)

- Business Type: Henan Herm Machinery Co., Ltd.,Manufacturer

- Market: Africa,Middle East

- Founded Year: 2010

- Address: No.50 Futing Road, Fugou Industrial Park,Fugou County

- Contact: Merry Zhang