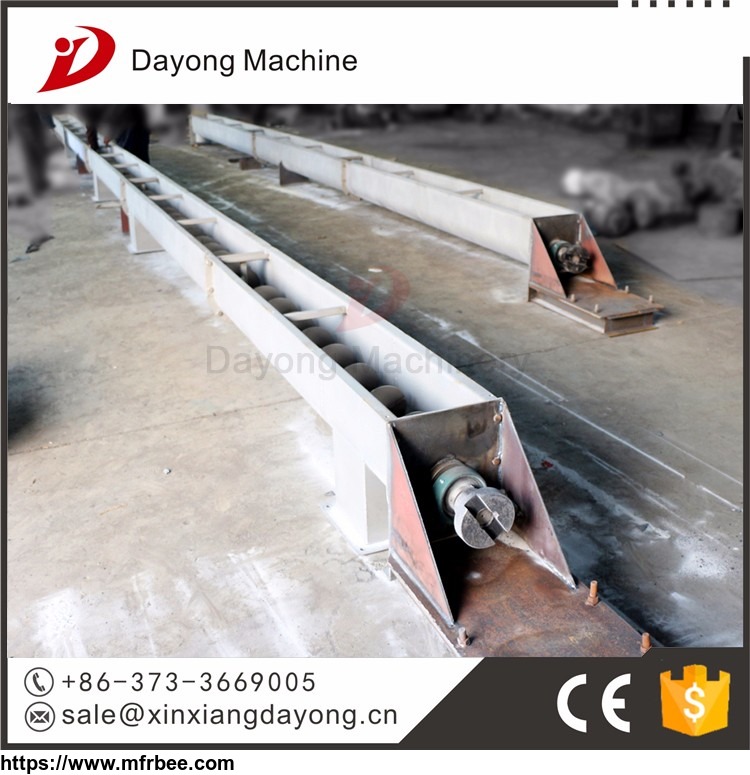

mine screw conveyer

Product Quick Detail

- Packaging

- Wooden packing. the packing size should be according to the actual size

- Delivery

- 15 Days

Specifications

working principle

a. There are two same vibration motor to be fixed on vertical screw slot. And they corotate by a contrary direction. The corotation will emerge a Centrifugal force to make a reciprocating motion

by the throwing direction.

b. Then the the vertical screw slot will begin to continuous vibrating. Then the material in the vertical screw slot will be threw to move up. In the process of Moving up, the material also can

be heat emission and cooled at the same time.

Applies to transport all kinds of powder, tablets, small block of bulk materials such as clay powder, coal, cement, sand, grains, small lump, pebble, and cast-iron chips and so on. Not suitable

for conveying sticky, easy caking, perishable materials.

The product is particularly suitable for the concrete mixing station from the cement silo to the mixer or from the cement silo to the batching of bulk cement transport between machines. Conveying

height of 6 meters, 8 meter

Inlet trough with progressive solid-flight screw for uniform storage bin discharge

Flexible coupling between the drive and the screw shaft

Bottom gates is optional for easy cleaning of the screw and trough

Hopper is adjustable and vibrational which make material to flowing easily

Hopper is separate from twisting shaft. Structure is reasonable andeasily loading and unloading

Easy assembly and replacement of component parts

They are compact and easily adapted to congested locations

They can be outfitted with multiple discharge points offering greater system design flexibility

- Country: China (Mainland)

- Market: 亚洲,美洲,欧洲,大洋洲,非洲

- Founded Year: 1987

- Address: The Fifth Room From West, 1st Floor, Building 18, Huilong Yangguang City, New District, Xinxiang, Henan, China (Mainland)

- Contact: cathy feng