Cable Tray

Product Quick Detail

- FOB Price

- USD $500.00 / Piece

- Minimum Order

- 500

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

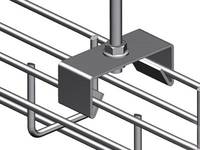

Cable Tray- Insulated Channel Types

Cable tray can be made of low carbon steel, FRP or stainless steel. The low carbon steel has various surface treatment for excellent corrosion resistance performance. The main surface treatments are pre-galvanized, hot dipped galvanized and powder coated. When the cable tray is cut into needed lengths, the cut surface will be painted with a zinc-rich compound to resist acid, alkali and other chemical erosion.

CT-01: Aluminum cable tray.

CT-02: Stainless steel cable tray.

Cable tray can provide the maximum protection to the cables due to its special structure. but the insulation structure require cutting the channel or using fittings to enter or exit cables.

We can not only supply the different materials of cable tray for you, we can also supply all kinds of fittings for you. The main fittings are as follows, refer to them and choose these if you need.

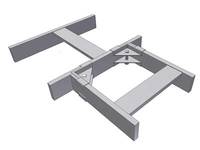

Elbow 90° cable tray.

Tee cable tray.

Cross cable tray.

Features of cable tray

- Interference resistance. The insulation structure make it possible to resist the interference.

- High corrosion resistance. The high quality material and excellent ant-corrosive surface treatment make the cable tray has perfect corrosion resistance performance.

- Long service life. The hot dipped galvanized surface treatment can extend more than twenty years of service life.

- Fire and flame resistance. The insulation structure can protect cables from fire and flames.

- Durable and long service life. Different materials and surface treatment can ensure the long service life and good condition.

Specifications of cable tray

- Material: low carbon steel, FRP, stainless steel.

- Surface treatment: pre-galvanized, hot dipped galvanized, powder coated.

- Width: 40 mm - 600 mm.

- Height: 40 mm - 200 mm.

- Length: 2440 mm, 2500 mm, 3000 mm.

- Thickness: 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 2.0 mm or 2.5 mm.

- Color: white, gray, orange, green or any other colors can be customized.

| Item | Height (mm) | Width (mm) | Thickness (mm) |

|---|---|---|---|

| CCTS-01 | 40 | 60 | 0.8/1.0/1.2/1.5 |

| CCTS-02 | 50 | 50 | 0.8/1.0/1.2/1.5 |

| CCTS-03 | 50 | 75 | 0.8/1.0/1.2/1.5 |

| CCTS-04 | 50 | 100 | 0.8/1.0/1.2/1.5 |

| CCTS-05 | 50 | 150 | 0.8/1.0/1.2/1.5 |

| CCTS-06 | 50 | 200 | 0.8/1.0/1.2/1.5 |

| CCTS-07 | 50 | 250 | 1.0/1.2/1.5/2.0 |

| CCTS-08 | 50 | 300 | 1.0/1.2/1.5/2.0 |

| CCTS-09 | 75 | 100 | 0.8/1.0/1.2/1.5 |

| CCTS-10 | 75 | 150 | 0.8/1.0/1.2/1.5 |

| CCTS-11 | 75 | 200 | 1.0/1.2/1.5/2.0 |

| CCTS-12 | 75 | 250 | 1.2/1.5/2.0 |

| CCTS-13 | 75 | 300 | 1.2/1.5/2.0 |

| CCTS-14 | 75 | 40 | 1.2/1.5/2.0 |

| CCTS-15 | 100 | 100 | 1.0/1.2/1.5/2.0 |

| CCTS-16 | 100 | 150 | 1.2/1.5/2.0 |

| CCTS-17 | 100 | 200 | 1.2/1.5/2.0 |

| CCTS-18 | 100 | 250 | 1.2/1.5/2.0 |

| CCTS-19 | 100 | 300 | 1.2/1.5/2.0 |

| CCTS-20 | 100 | 400 | 1.5/2.0 |

| CCTS-21 | 100 | 500 | 1.5/2.0 |

| CCTS-22 | 150 | 150 | 1.2/1.5/2.0 |

| CCTS-23 | 150 | 200 | 1.2/1.5/2.0 |

| CCTS-24 | 150 | 300 | 1.2/1.5/2.0 |

| CCTS-25 | 150 | 400 | 1.5/2.0 |

| CCTS-26 | 150 | 500 | 1.5/2.0 |

| CCTS-27 | 150 | 600 | 2.0 |

| CCTS-28 | 200 | 400 | 2.0 |

| CCTS-29 | 200 | 500 | 2.0 |

| CCTS-30 | 200 | 600 | 2.0 |

Applications of cable tray

The cable tray is mainly used for cable management in commercial and industrial constructions, such as power, distribution and communication. The cable trays are especially useful in situations where changes in wiring system are anticipated since new cables can be installed by laying them in the channel, instead of pulling them through a pipe.

- Country: China (Mainland)

- Business Type: Other

- Market: Europe

- Founded Year: 1996

- Address: East Industrial Zone, Anping, Hebei, China.

- Contact: dong feng