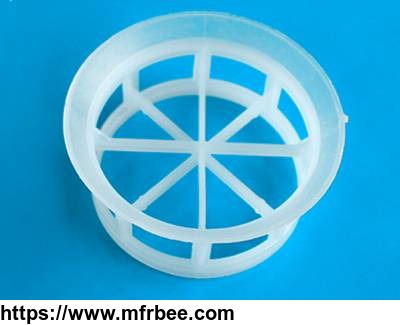

Plastic Cascade Mini Ring Increases Mechanical Strength

Specifications

Plastic Cascade Mini Ring for Rectification Towers

Plastic cascade mini ring adopts trumpet-shaped design with several windows open on the surface, which increases the mechanical strength of the whole ring. Being asymmetry, plastic cascade mini ring is increased the chance of directional delivery. It has features such as high void volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60 to 150. Compared with metal cascade mini ring

PCMR-01: Plastic cascade mini ring has several windows open on the surface.

PCMR-02: Plastic cascade mini ring has uniform gas-liquid contact.

| Model | Nominal diameter (mm) | Diameter × Height × Thickness D × H × δ (mm) | Bulk number (m-3) | Bulk density (kg/m3) | Specific surface area (m2/m3) | Void volume (m3/m3) | Dry packing factor (m-1) |

|---|---|---|---|---|---|---|---|

| PCMRS-01 | DN 16 | 16 × 8.9 × 1.1 | 299136 | 135.6 | 370 | 0. 85 | 602.6 |

| PCMRS-02 | DN 25 | 25 × 12.5 × 1.4 | 81500 | 97.8 | 228 | 0.90 | 312.8 |

| PCMRS-03 | DN 38 | 38 × 19 × 1 | 27200 | 57.5 | 132.5 | 0. 91 | 175.8 |

| PCMRS-04 | DN 50 | 50 × 25 × 1.5 | 10740 | 54.8 | 114.2 | 0. 927 | 143.1 |

| SMRS-05 | DN 76 | 76 × 37 × 3 | 3420 | 68.4 | 90 | 0. 929 | 112.3 |

| Materials: PP, RPP, PE, PVC, CPVC, PVDF, etc. |

Features

- Strong corrosion resistance.

- Uniform gas-liquid contact.

- Small specific gravity.

- High mass transfer efficiency.

- Light weight.

- Low cost.

Application

For all these advantages, plastic cascade mini ring is widely used in the packing towers in petroleum industry, chemical industry, alkali-chloride industry, coal gas industry and environmental protection, etc.

Package

Packed in anti-moisture plastic bags, woven bags and jumbo bags.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Americas

- Founded Year: 1996

- Address: East Industrial Zone, Anping, Hebei, China.

- Contact: qiang Li