Plastic Rasching Ring - a Random Packing with Simple Structure

Specifications

Plastic Rasching Ring for Various Mass Transfer Applications

Plastic rasching ring is a kind of random packing with simple structure, made of polyethylene, polypropylene, polyvinyl chloride and other quality plastics. It is designed by F.Rasching in 1914. Being characterized by large flux, lightweight and excellent corrosion resistance, plastic rasching ring is suitable for various mass transfer applications, such as gas processing, heat transfer and catalyst support. Plastic rasching ring in different dimensions can be customized according to customers\' requirements.

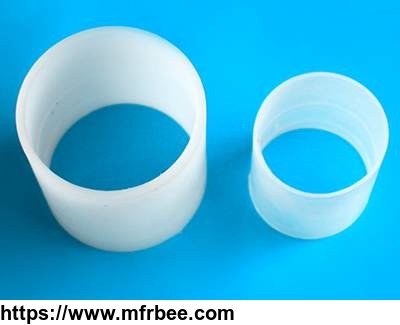

PRR-01: Plastic rasching ring is a kind of random packing with simple structure.

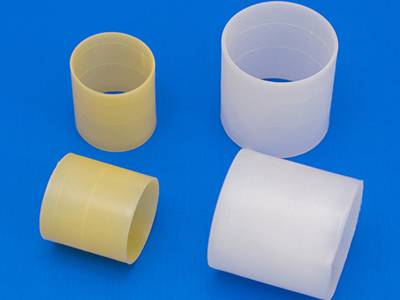

RPP-02: Plastic rasching ring is suitable for various mass transfer applications.

| Model | Nominal diameter (mm) | Diameter × Height × Thickness D × H × δ (mm) | Bulk number (m-3) | Bulk density (kg/m3) | Specific surface area (m2/m3) | Void volume (m3/m3) | Dry packing factor (m-1) |

|---|---|---|---|---|---|---|---|

| PRRS-01 | DN 25 | 25 × 25 × 1.0 | 48500 | 88 | 460 | 0.84 | 335 |

| PRRS-02 | DN 50 | 50 × 50 × 1.5 | 6500 | 65 | 236 | 0.90 | 240 |

| Materials: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride). |

Features

- Simple structure.

- Lightweight.

- Large flux.

- Low pressure drop.

- Good corrosion resistance.

- Economical.

- Various mass transfer applications.

Application

Being good at separation and absorption, plastic rasching ring is widely applied in petrochemical engineering, water treatment processing, gas processing and many other fields and industries.

Package

Covered with plastic bags & packed in carton boxes.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Americas

- Founded Year: 1996

- Address: East Industrial Zone, Anping, Hebei, China.

- Contact: qiang Li