FZB505 EDGE BANDER

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- STANDARD SEAWORTHY PACKAGE

- Delivery

- 20 Days

Specifications

Adopt the linear sealing of PVC, wood plank and veneer etc.

1.Using imported quality engines and electric components.

2.Serialized products, a wide range of selection by customers.

3.High precision and efficiency.

DETAILS SHOWS

FEATURES

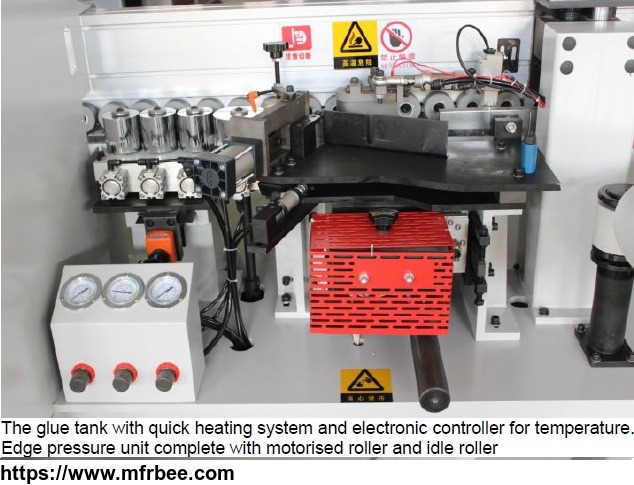

1.The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

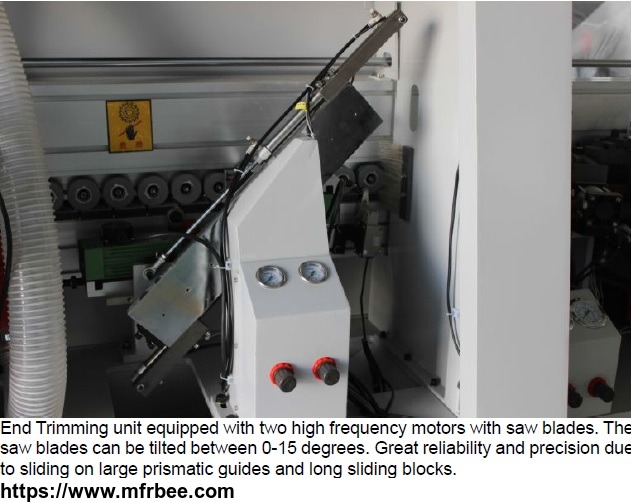

2.End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

3.Fine Trimming Unit ,with two individual high frequency motors , trim the exceeding edge on the top and bottom side of the panel , ensure the top and bottom side of the edge smooth and even.

4.Scarping unit for a perfect finising of the applied edge .

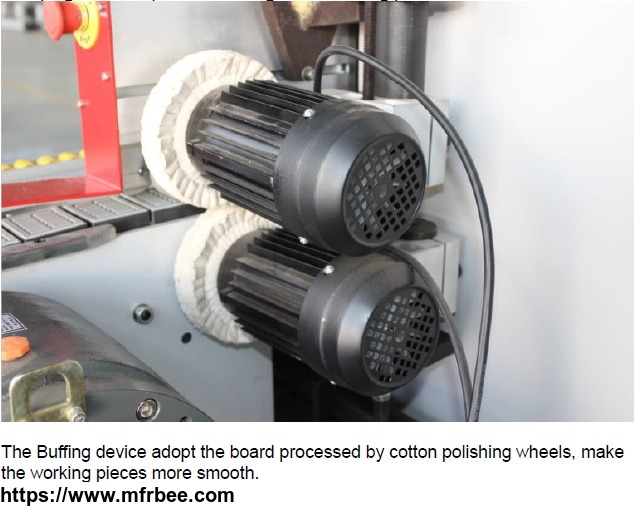

5.The buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

TECHNICAL DATA

| Pre-milling | / |

| Gluing | • |

| End trimming | • |

| Rough trimming | / |

| Fine trimming | • |

| Profiling unit | / |

| Scraping | • |

| Buffing | • |

| Grooving | / |

| Motor power | 9.2kw |

| Overall size | 4150*1100*1600mm |

| Feed speed | 12~20m/min |

| Panel thickness | 10~60mm |

| Edge banding tape thickness | 0.4~3mm |

| Panel width | ≥40mm |

| Working air pressure | 0.8MPa |

| Weight | 1900kg |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Emerging Markets,Middle East,Oceania

- Founded Year: 2014

- Address: Woodworking Industrial park,Qingdao,China

- Contact: Ann wei