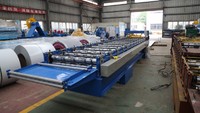

Steet Metal Roof Panel Roll Forming Machine

Product Quick Detail

- FOB Price

- USD $15,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily f

- Delivery

- Shipped in 45 days after payment

Specifications

1. Details of roof panel roll forming machine

| Material | ||

| Material Thickness(&):0.3 - 0.6mm | ||

| Applicable material:Galvanized Steel Coils, Hot Rolled Coils,Cold Rolled Coils,yield strength 245Mpa or 550Mpa | ||

| Machine Components | ||

| 1)Manual Decoiler: one set | ||

| Max. feeding width: 500mm, coil ID range 470mm±30mm | ||

| Capacity: Max. 3Ton |  | |

| 2) Cold Rolling Mills: | ||

| With feeding material guide, body frame made from 300# type steel by welding; | ||

| Side wall thcikness: 16mm | ||

| Rollers manufactured from bearing steel GCr15,precision machined,hard Chrome Coated with thickness 0.04mm(for longer life and anti-rust); |  | |

| Shafts manufactured from 45#,Main Shaft Diameter=φ75mm,precision machined | ||

| Motor Driving,Gear chain transmission, 14 forming stations and 7 rollers(3 upper rollers and 4 down rollers)for straightening and levelling) | ||

| Main Motor=4.0KW , Frequency speed control | ||

| Forming speed approx.12-15m/min | ||

| 3)Hydraulic Cutting device | ||

| hydraulic motor: 1.5KW, Hydraulic pressure range: 0-16Mpa | ||

| Cutting tool material: Cr12, Heat treatment | ||

| 4)PLC Control System(Touch screen brand:Taiwan WEINVIEW,Inverter brand:Finland VOCAN/Denmark Danfoss ,Encoder brand: Japan Koyo) | ||

| Control the quantity and punching,cutting length automatically | ||

| Combined with: PLC, Inverter, Touch Screen, Encoder, etc | ||

| Cut-to-length tolerance≤±1mm | ||

| Control Voltage 24V | ||

| 5) Exit Rack Un-powered, two units | ||

|

2. Main Features of roof panel roll forming machine

The advantages of roof panel roll machine are as follows:

1.Easy operation, low maintenance cost

2. save material

3. Detailed Images of Roof Panel forming machine

Machine Parts

Name: roof panel roll forming machine feeding device

Brand: BMS

Original: China

make the steel materials move more smoothly

Machine Parts

Name: roof panel rool forming machine cutter

Brand: BMS

Original: China

made by high quality mold steel Cr12 with heat treatment

Machine Parts

Name: rollers

Brand: BMS

Original: China

Rollers manufactured from high quality bearing steel 45#, CNC lathes, Heat Treatment.With black treatment or Hard-Chrome Coating for options.

Machine Parts

Name: PLC control system

Brand: SIEMENS/SCHNEIDER ELECTRIC

Original: Germany/France

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Encoder: KOYO/Omron (Japan brand

- Contact: Pablo Ai