YX23-845 Metal Roof Panel Roll Forming Machine

Product Quick Detail

- FOB Price

- USD $12,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Main body of YX23-845 Metal Roof Panel Roll Forming Machine is naked and covered by plastic film(to protect of dust and corrosio

- Delivery

- Shipped in 45 days after payment

Specifications

| SPECIFICATIONS FOR YX23-845 Metal Roof Panel Roll Forming Machine | |||

| DECOILER | Manual type | no power,5Ton*1200mm | coil inner–diameter=508mm; Load capacity=MAX.7.0Ton, Coiler Width=1200mm |

| Hydraulic type | 7Ton*1250mm | Load capacity=MAX.7Ton; Hydraulic system expand coil inner hole, Pump motor: 2.2KW;Coil inner–diameter=420-520mm; Coil Width=MAX.1250mm; Drag-off rotation type | |

| Main performance parameters of MAIN ROLL FORMING MILL | Main motor capacity | kw/h | 4 KW |

| Forming station | 14 | ||

| Forming speed(not incl.punching&cutting) | meter per minute | about 12 | |

| Hydraulic Punching and Cutting system | Hydraulic system | MPa | 16(max.) |

| Hydraulic drive | kw/h | 1.5 | |

| Cutting tool material | Tool steel | Cr12 |

Main Features

The advantages of Metal Roof Panel Roll Forming Machine are as follows:

1.Assembly process meets export standards, body frame and sideboard are spray-painted, other parts are finished through baking/chroming/galvanizing/blackening respectively, then unified assembly. After surface treatment, not only extend lifetime, but also improve overall appearance.

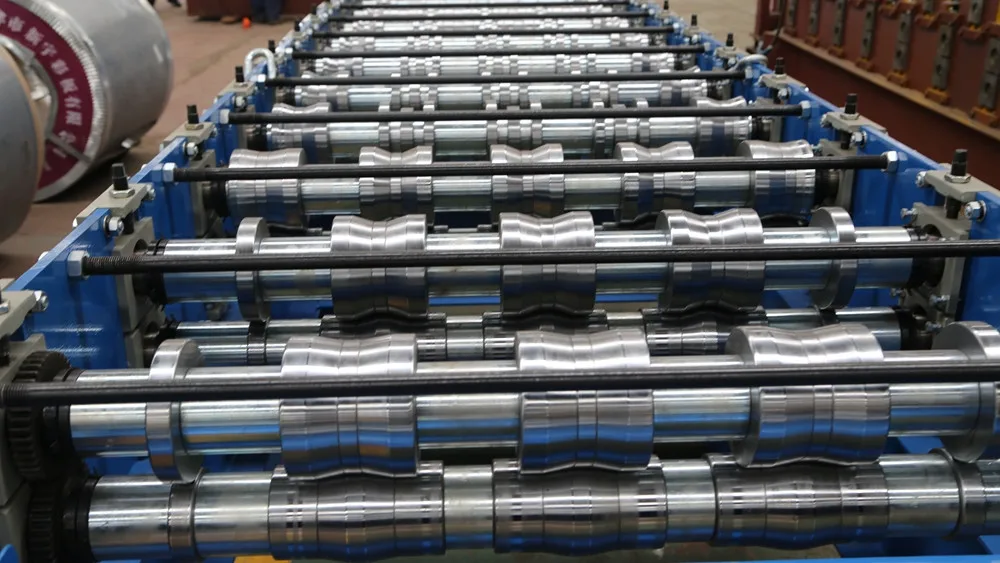

2.Manufactured from 45# steel, CNC lathes, Heat Treatment, hard Chrome Coated, surface with mirror treatment (more wearable and rust-free)

3.Rolling shafts are with precision machined. Solid core, ∮100mm, the material thickness increased to 1.5mm

4.Hydraulic cutting device, make the cutting smooth and neat.

5.Easy operation, low maintenance cost

Machine Parts

Name: Metal Roof Panel Roll Forming Machine cutter

Brand: BMS

Original: China

made by high quality mold steel Cr12 with heat treatment

Machine Parts

Name: Metal Roof Panel Roll Forming Machine shaft

Brand: BMS

Original: China

made by high quality mold steel Cr12 with heat treatment

Machine Parts

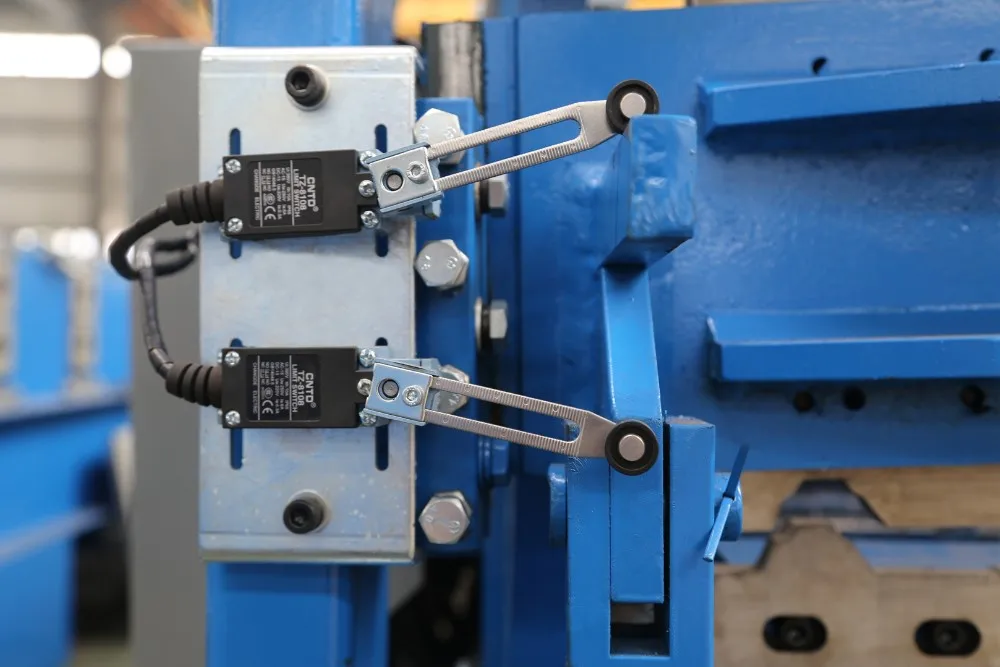

Name: Limit Switch

Brand: BMS

Original: China

Protect the cutter from being damaged

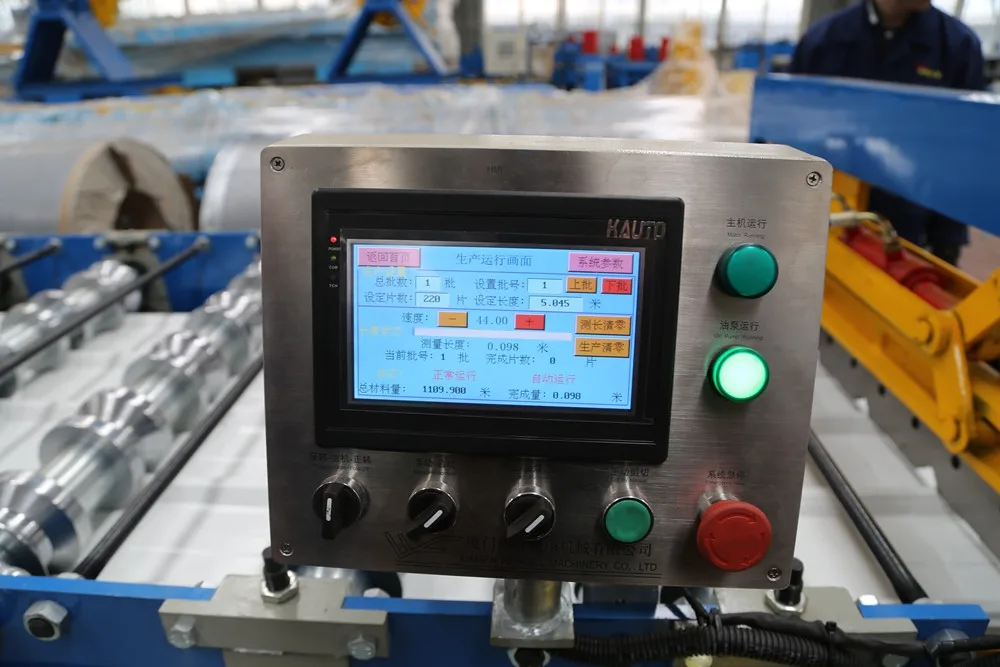

Machine Parts

Name: PLC control system

Brand: SIEMENS/SCHNEIDER ELECTRIC

Original: Germany/France

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Encoder: KOYO/Omron (Japan brand)

- Contact: Pablo Ai