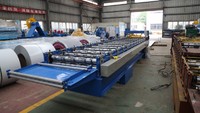

YX15-900 Wall Panel Roll Forming Machine

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Main body of YX15-900 Wall Panel Roll Forming Machine is naked and covered by plastic film(to protect of dust and corrosion),loa

- Delivery

- Shipped in 45 days after payment

Specifications

Product Application

Roll forming Machine for Wall Panel. Product is updated traditional roofing forming machine, the machine mainly by loading rack, loading rack bearing, feeding into platform, forming machine, molding shear device, hydraulic station, computer control box sections.

By the production of a variety of hidden roof panel to solve the conventional series of roof leakage problem, 470 pressure plate connected broke traditional roofing screw gun connection with practice, installation method of color with 45 degrees LAN mouth bite installation, roof waterproof effect is better.

| SPECIFICATIONS FOR YX15-900 Wall Panel Roll Forming Machine | |||

| DECOILER | Manual type | no power,7Ton*1200mm | coil inner–diameter=508mm; Load capacity=MAX.7.0Ton, Coiler Width=1200mm |

| Hydraulic type | 7Ton*1250mm | Load capacity=MAX.7Ton; Hydraulic system expand coil inner hole, Pump motor: 2.2KW;Coil inner–diameter=420-520mm; Coil Width=MAX.1250mm; Drag-off rotation type | |

| Main performance parameters of MAIN ROLL FORMING MILL | Main motor capacity | kw/h | 4.0 |

| Forming station | 9 | ||

| Forming speed(not incl.punching&cutting) | meter per minute | about 12-15 | |

| Hydraulic Punching and Cutting system | Hydraulic system | MPa | 16(max.) |

| Hydraulic drive | kw/h | 1.5 | |

| Cutting tool material | Tool steel | Cr12 |

Main Features

The advantages of YX15-900 Wall PanelRoll Forming Machine are as follows:

1.Assembly process meets export standards, body frame and sideboard are spray-painted, other parts are finished through baking/chroming/galvanizing/blackening respectively, then unified assembly. After surface treatment, not only extend lifetime, but also improve overall appearance.

2.Manufactured from 45# steel, CNC lathes, Heat Treatment, hard Chrome Coated, surface with mirror treatment (more wearable and rust-free)

3.Rolling shafts are with precision machined. Solid core, ∮80mm, the material thickness increased to 0.8mm

4.Hydraulic cutting device, make the cutting smooth and neat.

5.Easy operation, low maintenance cost

- Contact: Pablo Ai