Carpet Shredder Knives with High Wear Resistance

Product Quick Detail

- Place Of Origin

- Chian(Mainland)

- Packaging

- anti-rust oil ,plastic bag , plywood case (or as customers' request)

- Delivery

- depends on your quantity(usually within 3--4 weeks )

Specifications

Material: made out of different materials depending on cutting application ,working environment etc. wearable metals as 6CrW2Si, 42CrMo,SKD-11,D2,DC53,LD,Cr12MoV.

Advantages of Carpet Shredder Knives/Blades manufacturer and supplier:

1,We are end manufacture, we have competitive price.

2,More than twenty-six years experience.

3,Each technical index reaches the international standard.

4,Passed the ISO9001 quality certification in 2002.

5,OEM /ODM service.

6,Short delivery time, good packaging.

Features of Carpet Shredder Knives/Blades for recycling industry:

1, Through salt bath quenching or vacuum quenching to ensure the hardness.

2, Through triple tempt for optimum wear resistance.

3, high intensity, high toughness, anti vibration, small thermal deformation.

4, It has low noise and large moment of torsion on the basis of rotary blade V design.

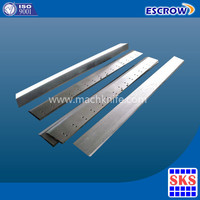

Specifications:(customized shape and dimension is acceptable!)

The specifications of usual type is :

Diameter: 200mm-500mm Thickness: 20mm-55mm.

Normal shape of the inner hole is sexangle or octangle ,circle with keyway ( as customer’s request)

Application of Carpet Shredder Knives/Blades for recycling industry::

This type shaft shredding machine blades for shredding and crushing metals, electronic scrap , recycling plastic and rubber lumps or wood in big size , PS, PP, PA, PE, PVC, PC material blowing film, rolling film, large plastic pipes, waste paper and film ,and sheet material.

Located in a highly industralized area,Ming Jue Industrial Park,SKS Industrial Cutter Solutions has been manufacturing and resharpening knives since 1988.

SKS is known as a credit and quality focused manufacturer of machine knives for many industries.SKS is able to examine all of your cutting applications and offer you the very best solutions to help improve your cutting performance and accuracy.This, of course, means added value to your products.Machine Knives and Blades can be manufactured precisely to customers' specifications on receipt of CAD drawings or samples or shop prints signed off for approval.

Our main products:

Metal working blades and tools:Coil Slitter Knife, Shear Blade, Bow-Tie Shear ,Steel Mills Knives, Scrap Chopper Knife, Pipe and Tube Mill Knife, Rubber-Bonded Spacer, Separator Disc, Aluminium Spacer etc.

Paper converting blades: rewinder slitter knives, Cylinder Paper Knife,log saw blade, Paper Guillotine Knives, Polar Cutting Blades, Perforating Knives, carton box slotter knives, Cardboard circle thin edge slitting knife etc.

Recycling blades: Plastics Processing Knives, granulator blade, Pelletizer Knives ,Shredder Cutter Knives, Crusher Knives, Plastic Film Three Hole Blade, Counter Knife etc.

Wood working blades: Wood chipper blades ,flaker knives,rechipper knives,veneer knives, Pressure /nose Bars, Wood Grinder Blade.,Veneer Slicer Knife.

Circular converting blades: Our circular converting knives have passed the ISO9001quality management system certification, covering the paper industry, plastic processing industry, leather processing industry, rubber processing industry, wood processing industry and other industries. Our circular knives including top slitter, bottom slitter, flat slitter, dish slitter, folding blades etc.

Solid and inlaid blades: SKS carry on Solid, Inserted or Brazed Inlay, Bolt-on designs to meet different applications. Inlaying process is what our product line features. The same time when we make our knives run longer, we are basing on ''cost-effectiveness''.

There are mainly two types of inserted blades: HSS tipped blades and Tungsten Carbid tipped blades.

1,HSS tipped knife - high red hardness & fine edge retention,it is particularly

suitable in thermal stress situations and for intermittent cutting

2,Tungsten Carbide Tipped Knife - or TCT Knife, provides exceptional fatigue ,shock

and wear resistance when cutting difficult-to-machin steels,high-alloy metals etc.

Welcome your inquiry and visiting!

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 1992

- Address: No.9 Mingjue Industrial Park,Lishui Nanjing,China

- Contact: May Zhu