Total Automatic Oil Water Separator

Product Quick Detail

- FOB Price

- USD $3,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

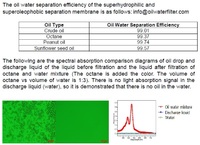

The total automaticoil water separator can be not only used in the situation of more water and less oil but also in the situation of more oil and less water. Thesuperhydrophilic and superoleophobic pleated filter cartridge and superoleophylic and superhydrophobic filter cartridge can be installed at the same time to realize that it outputs the purified water from superhydrophilic and superoleophobic pleated filter cartridge and outputs the purified oil from superoleophylic and superhydrophobic filter cartridge.

Features

Independent proprietary intellectual property rights:theoil water separation filter cartridge that the oil water separator employs has the independent proprietary intellectual property rights.

Flexible integration:they can be connected to be multi-level filtration system to remove solid and factice and then separate oil and water. The quantity of superhydrophilic and superoleophobic pleated filter cartridge and the quantity of superoleophylic and superhydrophobic filter cartridge can be adjusted as per the proportional of oil and water. For the situation of more water and less oil, the quantity of superhydrophilic and superoleophobic pleated filter cartridge is more than the quantity of superoleophylic and superhydrophobic filter cartridge, and vice versa.

Easy to use:it can be automatically operating when pipe is connected, valve is opened and pump is started.

Perfect efficiency:the workload of oil water separator ranges from 1 t/h to 50 t/h as per the practical requirements. It can be continuously operating.

Lower cost:the filter cartridge can be reused after cleaning; the power assumption of equipment is lower.

Diverse applications:It is acid-resisting, alkali-resisting and thermostable. It can separate crude oil, vegetable oil, alkanes, benzene and liquid that is insoluble in water on the surface of the water.

Excellent effect:the multi-level oil water separation systemcan thoroughly separate oil from water, and oil in water can be reduced to 5 ppm to ensure environmentally friendly operations and be in compliance with environmental laws and regulations or internal ISO14001 Objectives and Targets.

No pollution:It doesn’t need any oil sorbent additive. The equipment and its component don’t have any direct pollution and secondary pollution. The material itself can be degraded automatically, and can be burned as fuel.

Applications

To recover the valuable oil in chemical industry.

To remove the floating oil and oil film for ballast water.

To dewater from vegetable oil in food industry to realize oil purification.

To dewater from diesel oil, gasoline, jet fuel, engine oil, light oil, heavy oil and so on to realize oil purification.

Toremovethe floating oil and oil film in thewaste water pool in waste water treatment plant, so that it is easier to do water treatment than before.

To remove the floating oil and oil film in the waste water pool in industrial plantto meet environmental protection standards of discharge water.

To remove and recover the oil film from produced water and reinjection water in crude oil exploration.

To remove oil film from the used cutting fluid in machine industry.

Burst oil leaking accident, emergently dispose in the shortest period to protect environment and avoid social panic.

Emergency reserve to increase the treatment efficiency at the offshore drilling platform, offshore oil production platform, FPSO, ship, petrochemical plant, LNG plant, oil storage tank area, other oil plants, airport, seaport, dock, water treatment plant, official emergency treatment center and so on.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company,Distributor/Wholesaler

- Market: Africa,Americas,Asia,Europe,European Union,Middle East,Oceania

- Founded Year: 2017

- Address: No.42, Xianghu Road, Xiaoshan District,

- Contact: Maverick Guo