Packaging Machine

Product Quick Detail

- FOB Price

- USD $500,000.00 / Piece

- Place Of Origin

- China (Mainland)

- Minimum Order

- 1

- Packaging

- Plywoodcasepacking

- Delivery

- 15 Days

Specifications

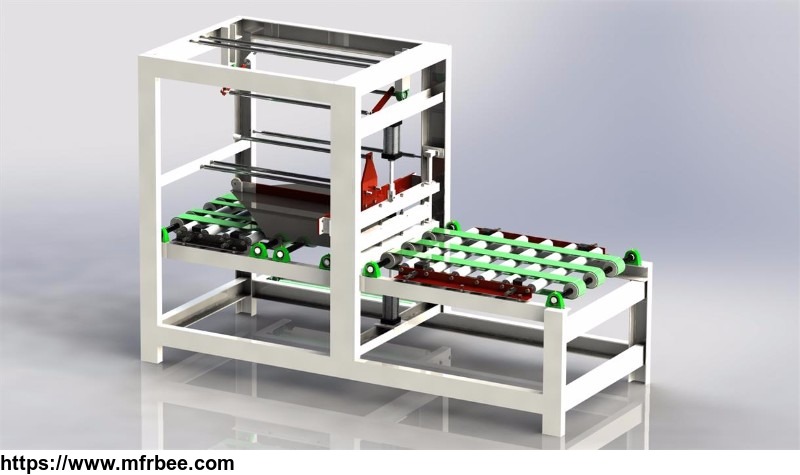

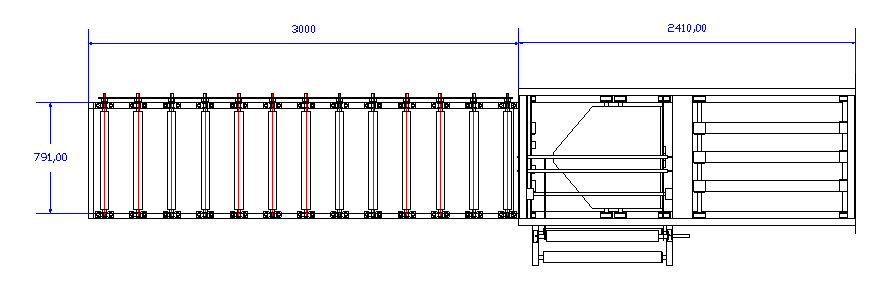

Heat Shrink Machine

Specification:

| Dimensions | length 5.41m × width 1.1m × height 0.7m |

| Working speed | 8 packs a minute |

| Power | 3KW |

| Total mass | 780kg |

Advantages of packaging machine

In order to create the maximum benefit for yourself within the stipulated time, it is necessary to ensure that your food packaging production line runs well and there will be no errors in the production process, so as to avoid the occurrence of errors and failures as much as possible. The company gets the most benefit.

The level of automation is constantly improving in the manufacturing industry, and the scope of application is expanding. The automation operation in the packaging machinery industry is changing the way of operation of the packaging process and the processing methods of packaging containers and materials.

The packaging system that realizes automatic control can greatly improve the production efficiency and product quality, significantly eliminate the errors caused by the packaging process and printing labeling, effectively reduce the labor intensity of employees and reduce the consumption of energy and resources.

Revolutionary automation has changed the way manufacturing methods and their products are transported in the packaging machinery industry.

The design and installation of the automatic control packaging system has played a very significant role in improving the product quality and production efficiency of the packaging machinery industry, and in eliminating machining errors and reducing labor intensity.

Especially for the food, beverage, pharmaceutical, electronics and other industries, it is vital. The technology in automation and systems engineering is being further deepened and more widely used.

Main classification of packaging machinery

Packaging machinery has a variety of classification methods, according to the function can be divided into single-function packaging machine and multi-function packaging machine; according to the purpose of use can be divided into inner packaging machine and packaging machine;

According to the packaging variety, it can be divided into special packaging machine and universal packaging machine; it is divided into semi-automatic machine and fully automatic machine according to the level of automation.

There are many types of packaging machinery and there are many classification methods. From different viewpoints, there may be a variety of, according to the state of the product, there are liquid, block, granular, paste, body, electronic combination scale packaging, pillow packaging machine;

According to the packaging role, there are inner packaging, outsourcing packaging machine; according to the packaging industry, there are food, daily chemical, textile and other packaging machines; according to the packaging station, there are single-station, multi-station packaging machine; according to the degree of automation Points, there are semi-automatic, fully automatic packaging machines.

There are many classification methods for packaging machinery. Each classification method has its own characteristics and scope of application, but it has its limitations. From the general situation of packaging machinery in the world, the more scientific classification method is based on its main function. Classification, which captures the essence of things, and its basic classification is as follows:

First, the filling machine

A filling machine is a packaging machine that loads a precise number of packages into various containers. The main types are:

1. Volumetric filling machine: including measuring cup type, intubation type, plunger type, material level type, screw type, timing type filling machine.

2, weighing filling machine: including intermittent weighing, continuous weighing, weighing - centrifugation and other filling machines.

3. Counting filling machine: including single-piece counting type and multi-piece counting type filling machine.

Second, the sealing machine

The sealing machine is a machine for sealing a container filled with a package, and the main types thereof are:

1. No sealing material sealing machine: including hot pressing type, cold pressing type, fusion welding type, plug type, folding type and other sealing machine.

2. Sealing material sealing machine: including sealing type, rolling type, crimping type, pressing type and other sealing machine.

3, there are auxiliary sealing material sealing machine: including tape type, bonding type, nailing type, ligation type, stitching type and other sealing machine.

Third, wrap machine

The wrapper is a packaging machine that wraps the package in whole or in part with a flexible packaging material. The main types are:

1. Full wrap wrapper: including wrap-around, covered, body-fit, seam-type wrappers.

2, half-wrapped wrapper: including folding, shrinking, stretching, winding and other wrapping machines.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Europe,Africa

- Founded Year: 2000

- Address: Mita Road, Jinzhou City, Shijiazhuang, Hebei

- Contact: Liu Zhanheng