Gypsum Cornice Machine

Product Quick Detail

- Place Of Origin

- China (Mainland)

- FOB Price

- USD $500,000.00 / Piece

- Minimum Order

- 1

- Packaging

- plywoodcasepacking

- Delivery

- 15 Days

Specifications

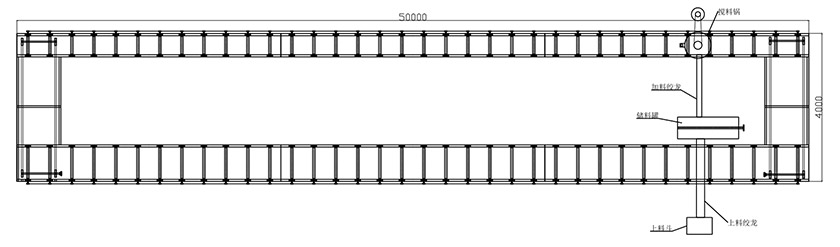

Gypsum Cornice Machine

Specification:

| Dimensions | length 50m × width 4m × height 0.7m |

| Working speed | 20m per minute |

| Power | maximum power 30KW |

The development direction of gypsum line assembly line equipment

Gypsum line equipment is called gypsum line assembly line equipment. In industrial production, the operation mode of gypsum line assembly line equipment has a relatively good rhythm, which not only can complete the various process requirements for production in production.

It can also better produce the production technology level of the production enterprise, achieve a certain proportion and balance; and through the independently driven variable frequency drive motor, the material can be flexibly stretched, lifted and lowered, and the gypsum line assembly line equipment application Wide range, able to meet the different needs of enterprise production, is an indispensable force to achieve industrial automation. So what is the prospect of plaster line assembly equipment?

1. Develop towards intelligence

Artificial intelligence is a new science and technology that enables computers to simulate certain thought processes and intelligent behaviors of human beings, understand the essence of intelligence, and produce a new intelligent machine that can react in a manner similar to human intelligence. The artificial intelligence technology is introduced into the automatic assembly line technology, so that the automatic assembly line system has the knowledge, experience and reasoning ability of experts.

2. Development towards integration

In the production process of the enterprise, the product design, production preparation, processing and manufacturing, production management and after-sales service are inseparable. Integration is to provide enterprises with integrated solutions for all aspects of production, and the integration of gypsum line assembly equipment to integration Can bring obvious results to the enterprise.

3. Development towards multi-functional direction

The process of designing the gypsum line assembly line equipment is a process for solving the constraint satisfaction problem, that is, the constraint description by a given function, structure, material and manufacturing, and the parameterization and variable design can greatly improve the mechanical design efficiency. It is one of the goals of the development of gypsum line assembly line technology.

Related product keywords:Gypsum Cornice Machine Brands

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Europe,Africa

- Founded Year: 2000

- Address: Mita Road, Jinzhou City, Shijiazhuang, Hebei

- Contact: Liu Zhanheng