Palletizer

Product Quick Detail

- FOB Price

- USD $500,000.00 / Piece

- Place Of Origin

- China (Mainland)

- Minimum Order

- 1

- Packaging

- plywoodcasepacking

- Delivery

- 15 Days

Specifications

Palletizer

Specification:

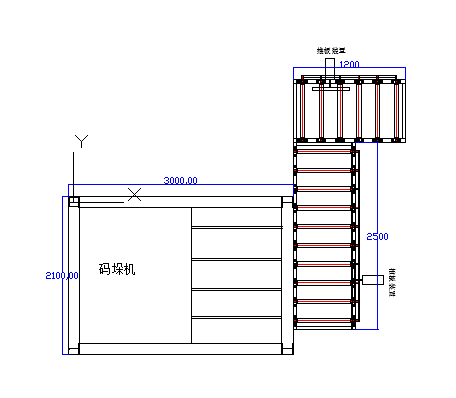

| Dimensions | length 1.2m × width 0.9m × height 0.6m length 2.5m × width 0.9m × height 0.6m length 3m × width 2.1m × height 2.9m |

| Working speed | 10 packs a minute |

| Power | 5KW |

| Total mass | 1600kg |

The palletizer is a carton that has been loaded into a container, placed on a pallet, a pallet (wood, plastic) according to a certain arrangement code, and automatically stacked, can be stacked in multiple layers, and then pushed out, so that the forklift can be transported to the warehouse for storage.

This equipment adopts PLC+ touch screen control to realize intelligent operation management, which is simple and easy to master. Can greatly reduce labor and reduce labor intensity.

The palletizing machine is a device that automatically transports the material bags, cartons or other packaging materials conveyed by the conveyor into the crucible according to the working mode of the customer's process, and transports the material into the crucible.

Introduction

The automatic palletizing machine is a high-tech product integrating machine and electricity. The medium and low-position palletizing machine can meet the production needs of medium and low output.

According to the required grouping method and the number of layers, the palletizing of various products such as bag, rubber block and box can be completed. The optimized design makes the shape of the dome tight and tidy.

classification

The automatic palletizer is divided into two categories according to the intelligent level: robot palletizer and mechanical palletizing. Mechanical palletizers can be divided into: gantry type palletizing machine, column type palletizing machine, and mechanical arm type palletizing machine.

According to the industry, automatic palletizers are divided into: food and beverage industry palletizing, cement automatic loading palletizing machine, industrial palletizing machine, etc.

Structural features

The middle and low position palletizers are mainly composed of flattening conveyor, slow stop conveyor, indexing conveyor, pallet bin, pallet conveyor, marshalling machine, push bag device, palletizing device and pallet conveyor.

Its structural design is optimized and the action is stable and reliable. The palletizing process is completely automatic, and there is no need for manual intervention during normal operation, and it has a wide range of applications.

working principle

The workpiece on the slab conforms to the stack of workpieces required by the pallet, and the slab and the workpiece move forward until the vertical plane of the pallet. The upper bar is lowered, and the other three positioning bar starts to clamp, and the plate is reset.

Each workpiece is lowered to the plane of the pallet, and the plane of the pallet is 10 mm away from the bottom surface of the panel, and the pallet is lowered by one workpiece height. Reciprocate the above until the pallet stacking code meets the set requirements.

The main purpose

The robot palletizer can be integrated into any production line to provide intelligent, robotic and networked production sites. It can realize palletizing logistics for a wide variety of operations in the beer, beverage and food industries. It is widely used in cartons, plastic boxes and bottles. Classes, bags, drums, film bags and filling products. It is equipped with three-in-one filling line, etc., and palletizes various types of bottles and bags.

The automatic operation of the palletizing machine is divided into automatic feeding, transfer, sorting, stacking, stacking, lifting, feeding, stacking, and exiting.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Europe,Africa

- Founded Year: 2000

- Address: Mita Road, Jinzhou City, Shijiazhuang, Hebei

- Contact: Liu Zhanheng