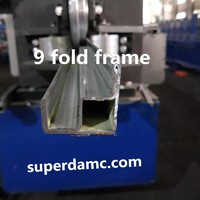

Control Panel Electric Cabinet 9 Fold Profiles Production Line

Product Quick Detail

- 46000

- 80000

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- Container

- Delivery

- 55 Days

Specifications

Control Panel Electric Cabinet 9 Fold Profiles Roll Forming Process Production Line

Cabinet frame roll forming system

The base is welded by a square tube

Number of roller station: 28 station

Roller shaft diameter: 65mm

Roller shaft material 45#

Roller material: GCr15 fine turning process with quenching

Two sets of 11 KW motors

Forming machine structure: wall panel structure

Transmission mode: industrial drive chain

Shenzhen Superda Machine Co., Ltd Professional in design electric enclosure, cabinet profiles fabrication machinery

https://www.superdamc.com

6, cut off

Cutting method: cut off the flying saw with water cooling

7, Electronic control system,

Speed control: inverter

PLC uses Panasonic brand

Encoder uses Omron brand

Touch screen adopts China Brand Touch Screen

The control system has its own power protection, overload protection, short circuit protection, and its own emergency stop button. (This button can be pressed if an accident occurs, and the device stops.)

- Country: China (Mainland)

- Business Type: Fire hose reel cabinet roll forming machine, Distribution box roll forming machine, filter frame roll forming machine, oval tube forming machine, square tube roll forming machine, triangular tube machine, electronic cabinet roll forming machine

- Market:Asia,European Union

- Founded Year:2009

- Address:No.95, Ainan Rd, Longdong district, Longgang area

- Contact:Demi Wu

Other products from Shenzhen Superda Machine Co.,Ltd

Relate products of Control Panel Electric Cabinet 9 Fold Profiles Production Line

Electrical cabinet 9 fold roll forming machine production line Machine parameter and technology 9 fold profile productionprocess Uncoiler → Leveling → Automatic feeding → Punching → Forming → Cutting →Collect Production speed: 0 -- 6 m / min 1, China standard 9 fold ...