Superda Distribution Box Eelectrical Enclosure Bending Machine Manufacturer

Product Quick Detail

- FOB Price

- USD $712,000.00 / Piece

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- Container

- Delivery

- 65 Days

Specifications

Explaination

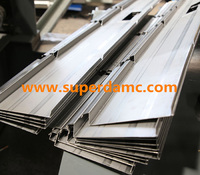

This production line is equipment for production of distribution boxes. The strip coil to be processed is manually placed on the uncoiler, and then corrected and tensioned. After leveling, it enters the hydraulic pre-punching and punching notch, and is sent to the forming machine by the guide device to form. Under the frictional damping action of the forming roller and pressure roller, after entering the bending part at a linear speed of 0-13m, the box is cut and bent as required, and then manually packed away. This production line produces 2-3 enclosures per minute. the production box quantity speed according to different product specifications.

三、Electric box production linemain technical parameters

1.Details of accessory brand

| No. | Name | manufacturer |

| 1 | Encoder | Omron |

| 2 | Touch Screen | Mitsubishi |

| 3 | Programmable controller (PLC) | Mitsubishi |

| 4 | Low-voltage circuit breaker | Chint |

| 5 | AC contactor | Chint |

| 6 | Inverter | Mitsubishi |

| 7 | Hydraulic Solenoid Valve | Shun Xin, Taiwan |

| 8 | Guide rail | Hiwin Taiwan |

| 9 | Server System | Mitsubishi |

2.Feeding specifications

a. Applicable materials: cold rolled coil, galvanized coil

b. Material quality: Domestic GB standard

c. Tensile strength: δb≤780Mpa (Max.)

d. Yield strength: δs≤510Mpa (Max.)

e. Material thickness: 1.0-1.5mm

f. Material width: 200-450mm (Max.)

g. Inner diameter of steel coil: Φ360mm-Φ510mm

h. Outside diameter of steel coil: Φ1250(Max.)

i. Steel coil weight: 3 t (Max.)

3.Forming parameters

a. Number of forming staion: 16 sets of roller

b. Spindle specification:Ø48mm 40Gr quenching and tempering

c. Roller material: Gr12 mold steel heat treatment

d. Integral archway: precision machined from 25mm steel plate, the hole distance error is less than 0.1mm

e. Base plate thickness: 20mm

4, forming ability

a. Outside diameter of coil: Φ1250mm (Max.)

b. Material forming thickness: 1.0-1.5mm

c. Product width 160mm-400mm adjustable

5.Speedparameters of forming unit

a. Linear speed 0-13m / min

b. Acceleration time<30 seconds

6, Forming accuracy

a. Shear length tolerance: ≤ ± 0.5mm / m

b. Width tolerance: ≤ ± 0.5mm

c. Sickle curve: ≤2mm / m

d. Burr: ≤0.1mm (new blade cutting ordinary carbon steel plate with reasonable clearance)

e. Height tolerance: ≤ ± 0.5mm

The above tolerances are based on the first-grade steel coils with flat and edgeless waves.

7.Other equipment parameters

a. Power supply: 380V / 50HZ / 3PH (Or Custmized)

b. Installed capacity: about 32Kw

c. Forming speed: 0-13m / min

d. Cutting method: forming then cutting

e. Driving motor:

Straightener machine motor 2.2KW

Hydraulic punching 15kw,bending and cutting 5.5KW

Forming host motor 7.5KW

Servo motor 2KW

f. Floor area (approximately): length 30m × width 3m

(Roll Forming 7mX1.5m)

g. Production line direction: from left to right

(facing the unit from the operation table).

h. Equipment color: (Customer choice)

i. Unit equipment design can meet 12 hours of continuous production

j. Operating environment:

1: power supply voltage: 380V ± 10% / three-phase four-wire, frequency: 50HZ total power: about 32KW

2: Ambient temperature: 0-40 ° C, relative humidity: 60-95% RH.

Devices:

| No. | Machine name | QTY | REMARK |

| 1 | Uncoiler | 1 | |

| 2 | Straightener | 1 | |

| 3 | Servo Feeder | 1 | 2kw Mitsubishi motor |

| 4 | Servo Hydraulic machine | With mould | |

| 5 | Guide device | 1 | |

| 6 | Forming machine | 1 | |

| 7 | Hydraulic bending cutting | 1 | With mould |

| 8 | Control system | 1 |

- Country: China (Mainland)

- Business Type: Fire hose reel cabinet roll forming machine, Distribution box roll forming machine, filter frame roll forming machine, oval tube forming machine, square tube roll forming machine, triangular tube machine, electronic cabinet roll forming machine

- Market:Asia,European Union

- Founded Year:2009

- Address:No.95, Ainan Rd, Longdong district, Longgang area

- Contact:Demi Wu

Inquires

-

wangmigel_manager20@MY,2020-05-13 19:00:56

Greetings Sirs and Madams,

Hope I find you in good health?

My name is Wang Miguel I am the Proprietor of MULTI SERVICE LLC, is a Retail and Trading company located in .....

Hope your company can receive order now?

Kindly Provide me with your website link/catalog via WhatsApp ........... as we are working from home so we can choose precisely the needed products required by our client. Await your message on our email contact address below ( Wangmigel_manager20@hotmail.com)

Regards,

Wang Miguel

Send inquiry / quota request to Superda Distribution Box Eelectrical Enclosure Bending Machine Manufacturer

Other products from Shenzhen Superda Machine Co.,Ltd

Relate products of Superda Distribution Box Eelectrical Enclosure Bending Machine Manufacturer

Roll forming machine for production power distribution box, including distribution panel forming machine, panel box bending. Distribution box roll forming machine production line Roll forming machine for production power distribution box, including distribution panel forming ...