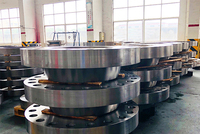

Forged Steel Valve

Product Quick Detail

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- Wooden Crate

- Delivery

- Within 30 days

Specifications

ZECOforged valve manufacturing process

Forged valve adopts the forging process, because the mechanical properties of castings is lower than the same material of forgings, and forgings are formed by casting after forging processing of raw materials, the original casting internal loose grain structure, as a result of the forging force become more closely, make better continuity of metal fibre, plasticity and mechanical properties of the metal.Forged gate valve manufacturers

As a industrialValve supplier

Forged Steel Gate Valve for Sale List

Forged Gate Valve

SW Gate Valve

Forged Globe Valve

A105 Globe Valve

SW Globe Valve

Forged Steel Check Valve for Sale List

Forged Check Valve

A105 Check Valve

Sw Check Valve

Forged Steel Ball Valve for Sale List

2pc Ball Valve

3pc Ball Valve

Two Piece Ball Valve

Three Piece Ball Valve

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:G20,Asia,Middle,Europe

- Founded Year:1991

- Address:No.3999, Cao'an Road, JiaDing District, Shanghai, China

- Contact:Jerry Zhao

Other products from ZECO VALVE GROUP CO., LTD.

Relate products of Forged Steel Valve

As a professional cast steel ball valve suppliers, MSTNLAND has high-quality cast steel ball valves for sale. Welcome to contact us if needed. There are many ball valve manufacturers, but we are one of the best choices for you. ...

Stainless Steel Gate valve Features Small flow resistance. Because the internal medium channel of the valve body is straight-through, the medium is flowing straight, so the flow resistance encounters is small. In order to make a reliable valve seal, it is reasonable to ...

Carbon steel forging with super toughness and bending strength. The hook is made of super high carbon steel with super toughness and bending strength. The hook has been forged, the hook point is sharp and not easy to break, and the penetrating force is strong. The surface is ...