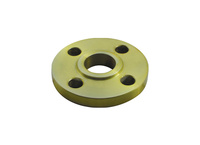

Flanges

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 21 Days

Specifications

Aflange

Standards & Sizes of Flanges

1)ANSI/ASME B16.5 Size: NPS 1/2"-24"

2)ANSI/ASME B16.47 Series A(MSS SP-44) Size: NPS 26"-60"

3)ANSI/ASME B16.47 Series B(API 605)Size: NPS 26"-60"

4)ASME B16.36 Size: NPS 1"-24"

5)DIN Standard Size: DN10-DN4000

6)BS 4504 Size: DN15-DN2000

7)BS 10 Size: DN10-DN3000

8)JIS B2220 Size: 10A-1500A

9)UNI Standard Size: DN10-DN2000

10)EN 1092-1 Size: DN10-DN400

Materials Used by Leading Flange

01

Carbon Steel: A105, RST37.2, C22.8, P235GH, P265GH, S235JR, A37, A42, etc.

02

Stainless Steel: F304/F304L, F316/F316L, F321, F44, F55, etc.

03

Other Alloy Steel: A350 LF2 F52/F60/F65/F70, etc.

Click on any of the models for further information or contact us directly to speak to us

about your particular requirements.

Flanges Manufacturing Process

Casting

The blank size of a casting flange is accurate, so it enjoys little processing volume. The advantage of castings is that they can produce more complex shapes and have a lower cost. But casting flanges have more casting defects (pores, crack), the internal organizational structure of the casting flanges is worse.

Forging

Let's take a look at the production process for forging flanges:

The forging process is generally composed of the selection of high-quality billet material, heating, forging, cooling. Forging methods include free forging, mold forging. When producing, forging methods are selected according to the size and the number of flanges to be produced.

The advantage of forged flanges is that the internal organization structure is uniform, and there are no pores, impurities, and other harmful defects;

Forged flanges can withstand higher shear and tensile forces than casting flanges.

The disadvantage is that forged flanges cost much more than casting flanges.

Cut Flanges

This method is to directly cut out the outer diameter of the flanges on the steel plate with suitable thickness, and then process the bolt holes and water lines. The maximum diameter of such flanges is limited to the width of the steel plate. The advantage of this method is low cost and the disadvantage is that only plate/blind flanges can be made by this method.

As one of aflange manufacturers

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact:hebei leading

Other products from Hebei Leading Metals & Piping Industries Co., Ltd.

Relate products of Flanges

Nill Building Solutions has revolutionized the flange that has been in use for decades by roofers worldwide by making it stronger, waterproof, and eliminating common trouble areas while improving on efficiency. Various sizes available to suite your needs. The NB1C is ideal for ...

DIN CAST IRON FLANGED GLOBE VALVE MstnLand runs a qualified cast iron globe valve factory in China. Our ductile iron globe valve series is mainly used for cutting off or connecting the medium in the pipeline, generally not used for regulating the flow. Body material: Grey cast ...