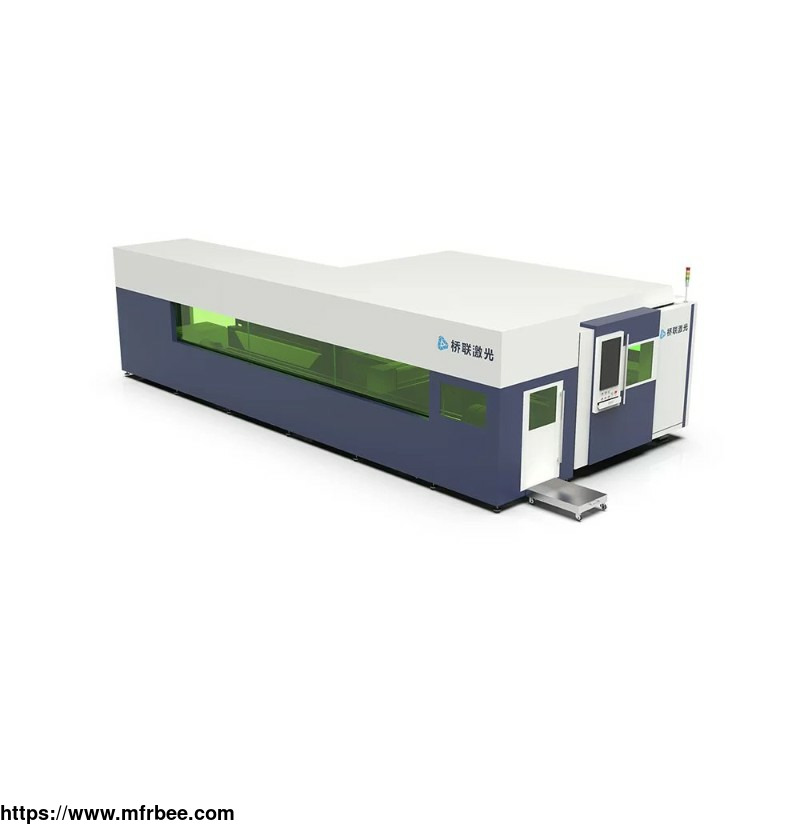

ALLIN ONE BOARD AND TUBE EXCHANGE MACHINE

Specifications

Double servo motor drive

With higher stability, higher speed and faster acceleration

Fully digital CNC servo motor communication

The exchange table reduces the time of loading and unloading and improves the cutting efficiency

Adopt gantry structure, imported gantry milling and finishing to ensure long-term normal use without deformation

The bed adopts an integral welding structure, rough machining after annealing, and then vibration aging treatment, which can completely eliminate the stress of welding and processing, with good rigidity, high precision, and can maintain long-term use without deformation

The beam is made of aluminum alloy cast as a whole, rough machined after two high temperature annealing, and then vibrated and aged, it has good rigidity, light weight and good dynamic performance after high-precision machining

Adopt Japanese SMC intelligent air group design, can automatically adjust pressure, automatic ventilation, pressure detection and other functions

Guide rails and racks are calibrated with a precise collimator with an accuracy of ±0.01mm

| Cutting Size (mm) | 3000x1500/4000x2000/6000x2000/6000x2300/6000x2500/8000x2300/8000x2500 |

| Chuck Size (mm) | 120/160/220/280/320/350 |

| Tube length | 3000/6000/7000/9000 |

| X/Y Axis Positional Accuracy (mm) | ±0.03 |

| Repeated Positional Accuracy (mm) | ±0.01 |

| Pepid Positioning (mm/min) | 90 |

| Max Acceleration (G) | 1.2 |

| The Max. number of revolutions of the chuck (RPM) | 80-120 |

| The Laser Power (W) | 1000-6000 |

- Contact: Al ma