Desand Cyclone and Germ Cyclone

Specifications

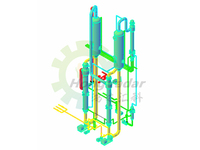

Desand Cyclone

HVD-CY-DS series desand cyclone is mainly used in starch production to remove sediment, metal particles, and other impurities in starch milk. The desanding hydrocyclone is also suitable for

removing heavy phase impurities in other fluids. There are two kinds of cyclone particle separator bodies: stainless steel & ceramic and high-strength wear resistant plastic. Advanced design, easy

installation, and high efficiency of sand removal.

Desand Cyclone Working Principle

Under the pressure of 0.5MPa, the starch milk enters along the tangent direction of the desander and generates centrifugal force due to the rotary movement. Due to the different specific gravity of

the material, the heavy phase impurities such as sand are thrown to the periphery and discharged along the inner wall from the bottom. And the starch milk overflows through its upper overflow pipe

into the next process.

Desand Cyclone Technical Parameters

HVD-CY-DS series desand cyclone

Model Capacity, m3/h Feed pres., MPa Desand efficiency, % Remarks

HVD-CY-DS1 30-35 0.5 ≥97 2+1 cyclones

HVD-CY-DS2 60-70 4+2 cyclones

HVD-CY-DS3 90-100 6+2 cyclones

HVD-CY-DS4 120-130 8+2 cyclones

HVD-CY-DS5 150-160 10+2 cyclones

Degerm Cyclone

HVD-CY-GM series germ cyclone separator use is mainly about separating the germ after the corn is coarsely broken. As one of the two types of cyclone separator, this equipment is static with simple

structure, advanced design, easy installation, and large production capacity range.

Germ Cyclone Working Principle

The crushed material enters from the tangent direction through the feeding inlet under a certain pressure. Due to the different specific gravity of the germ and the corn slurry, under the action of

centrifugal force, the free germ discharge through the overflow outlet, and the corn slurry is discharged from the lower part.

Germ Cyclone Technical Parameters

HVD-CY-GM series germ cyclone

Model Single cyclone capacity, t/h Feed pres., MPa

HVD-CY-GM12.5 1.5-2.0 0.5

HVD-CY-GM15 2.0-3.0 0.6

HVD-CY-GM22.5 8.0-10.0 0.7

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy-saving equipment system for the customer. The manufacturing

factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose international ISO, EU CE, and

other standards for equipment design and production according to their needs.

Desand Cyclone and Germ Cyclone Parameters

Desand Cyclone Technical Parameters

HVD-CY-DS series desand cyclone

Model Capacity, m3/h Feed pres., MPa Desand efficiency, % Remars

HVD-CY-DS1 30-35 0.5 ≥97 2+1 cyclones

HVD-CY-DS2 60-70 4+2 cyclones

HVD-CY-DS3 90-100 6+2 cyclones

HVD-CY-DS4 120-130 8+2 cyclones

HVD-CY-DS5 150-160 10+2 cyclones

Germ Cyclone Technical Parameters

HVD-CY-GM series germ cyclone

Model Single cyclone capacity, t/h Feed pres., MPa

HVD-CY-GM12.5 1.5-2.0 0.5

HVD-CY-GM15 2.0-3.0 0.6

HVD-CY-GM22.5 8.0-10.0 0.7

Beijing Hongvadar Engineering Technology Co. Is a professional corn processing plant, we provide single cyclone separator, liquid cyclone, stainless steel cyclone separator, hydrocyclone for sale

and etc. Want to know cyclone separator price and use of cyclone separator, contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com